Industrial Large Quintuple Tank With Automatic Robot Hand Cleaning Ship Parts Aerospace Components Jet Engine Nozzles

Industrial Ultrasonic Cleaner Manufacturer-Granbo Ultrasonic

Industrial Ultrasonic Cleaner Manufacturer-Granbo Ultrasonic

Industrial Large Quintuple Tank With Automatic Robot Hand Cleaning Ship Parts Aerospace Components Jet Engine Nozzles

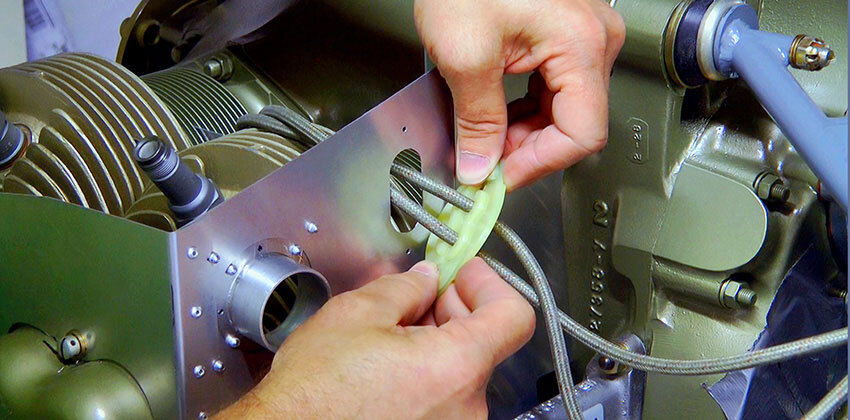

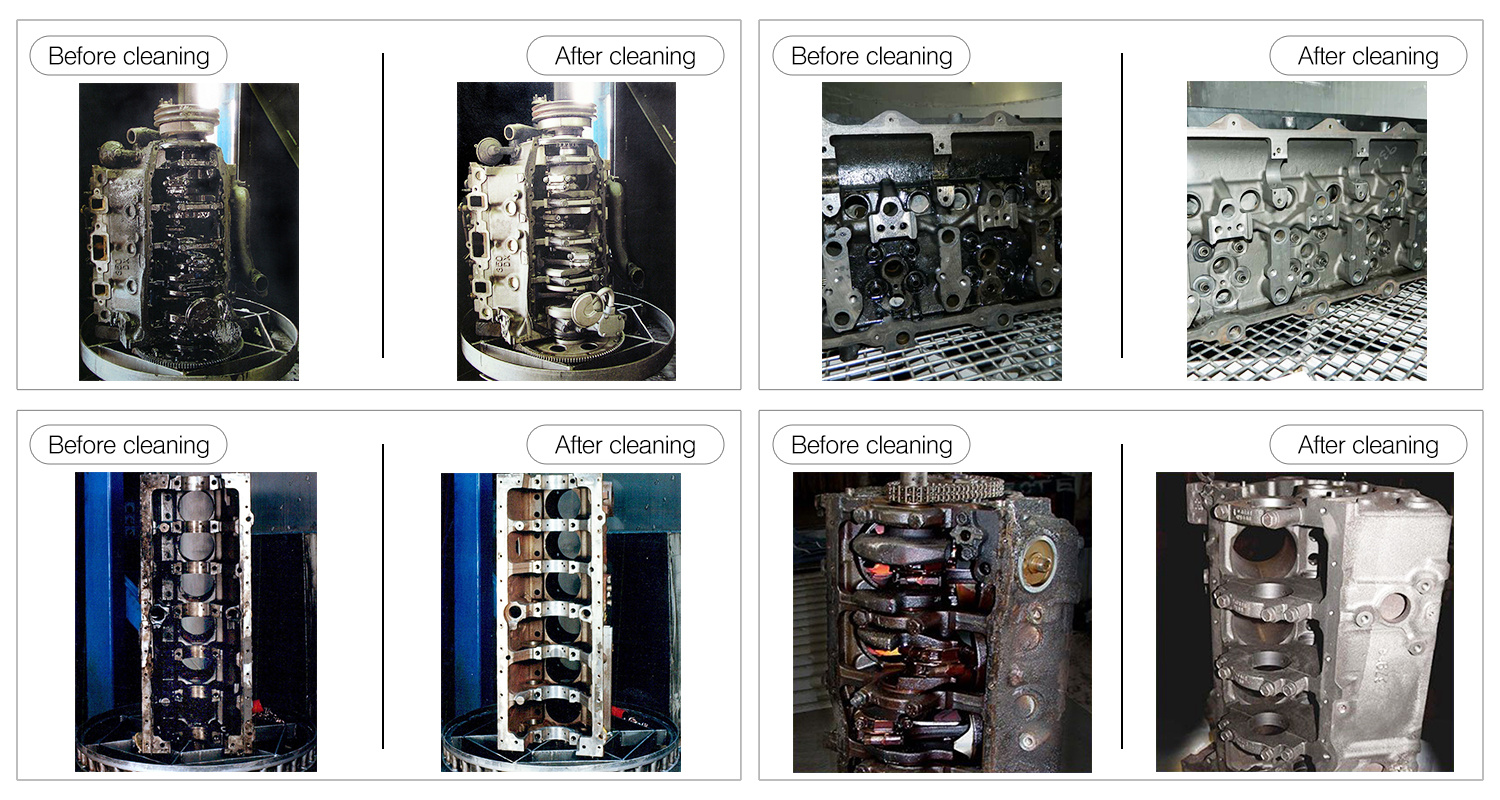

It can be hard to clean heavy loads and big components with light or heavy contamination without damaging them. Not only do they get covered with difficult-to-remove carbon buildup and grime, but many parts also present intricate surfaces as well as delicate components. Like aerospace parts, regular maintenance procedures are strictly prescribed for aircraft jet engines and include thorough cleaning and inspection of fuel nozzle assemblies. Now Granbo Technology Industrial is proud to introduce Industrial Ultrasonic Cleaning technology to these hard-cleaning objects: ship parts, aerospace components, large batches of smaller parts, heat exchangers, engine blocks.

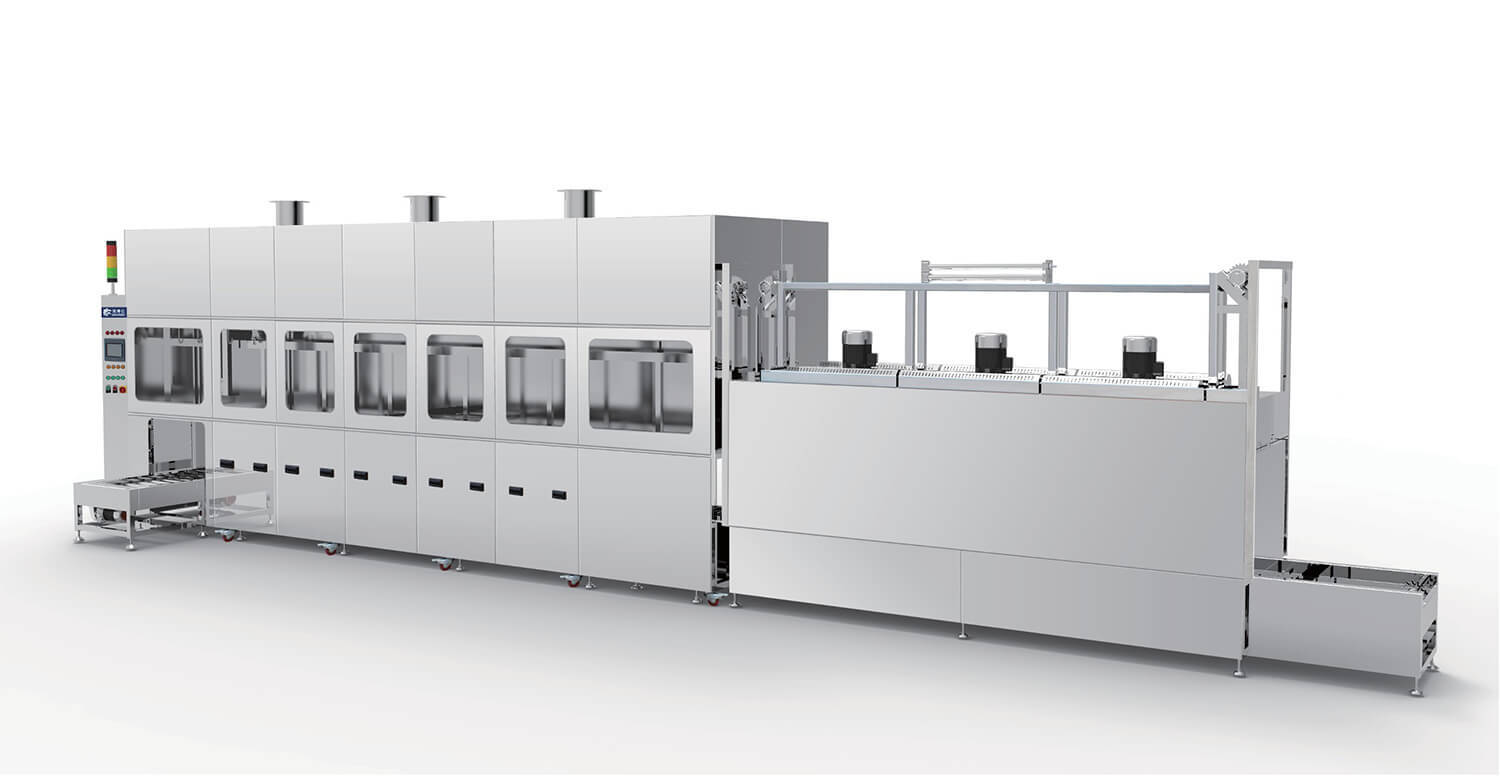

Full Automatic Ultrasonic Cleaner Assembly Line With Cursory Rinsing + Rinsing + Wind Knife Cut Water + Tunnel + Furnace Dry

PLC Control

Automatic Manipulator

Save Time

Save Manpower

Ultrasonic Acid/ Alkali Wash > Ultrasonic Cleaning + Filtration Cycle > Bubbling + Filtering > Water Blowing At Normal Temperature >hot Air Dry , Other Processes Can Be Customized

Fully Automatic Operation , Manual Feeding > The Machine Automatically Completes Every Step Of The Process > Manual Blanking

Ultrasonic cleaning can be used for many applications, including plastic parts, bearing, bolts, rubber parts, internal parts, plastic injection molds, transmission parts, and final cleaning of all engine parts prior to assembly, the versatility of ultrasonic cleaning machine make them the perfect choice for automotive, medical, pharmaceutical, aerospace, engineering and many other industries.

Simply put, ultrasonic sound waves are sound broadcast at a frequency beyond the normal range of human hearing. When ultrasonic waves move through a liquid and strike a hard surface, they produce millions of tiny bubbles, known as “cavitating bubbles.” These microscopic bubbles produce momentary jets of intense energy when they collapse, directing that energy against the surface they are collapsing against. Repeated millions of times and with the assistance of detergent present in the surrounding liquid, these bubbles scrub away almost any type of grime from all surfaces of an object, no matter how intricate it may be. Furthermore, unlike traditional brush and solvent methods, they generally do it without damaging the underlying object.