Industrial Ultrasonic Cleaner Manufacturer-Granbo Ultrasonic

Industrial Ultrasonic Cleaner Manufacturer-Granbo Ultrasonic

Industrial ultrasonic cleaners come in many sizes, shapes, and features, and have been widely used in the hardware, electronics, automotive, aviation industries. This guide will help you pick the equipment right for you.

What is an “Industrial” Ultrasonic Cleaner?

You might think an industrial ultrasonic cleaner must be “big” because it is handling industrial products. Not necessarily so. Your industrial parts washer size (or cleaning solution capacity) is governed by the size of parts you are cleaning. They are offered as benchtop and floor-mounted models.

Another consideration to keep in mind is the duration of your cleaning cycles. Long-term cleaning cycles (i.e. operating continuously over a work shift) mean your unit should have a heavy-duty tank to prolong service life.

Ultrasonic Cleaning through high-frequency vibration of the ultrasonic transducer to drive the oscillation of water or other liquid, so that more vacuum micro-bubbles are generated in the solution, and bubbles in the process of increasing the implosion, resulting in thousands of pressure impact strength, constantly impacting on the surface of the object to peel off the dirt. Therefore, ultrasound cleaning has microporous permeability and super peelability, so it is more efficient and energy-saving than traditional cleaning.

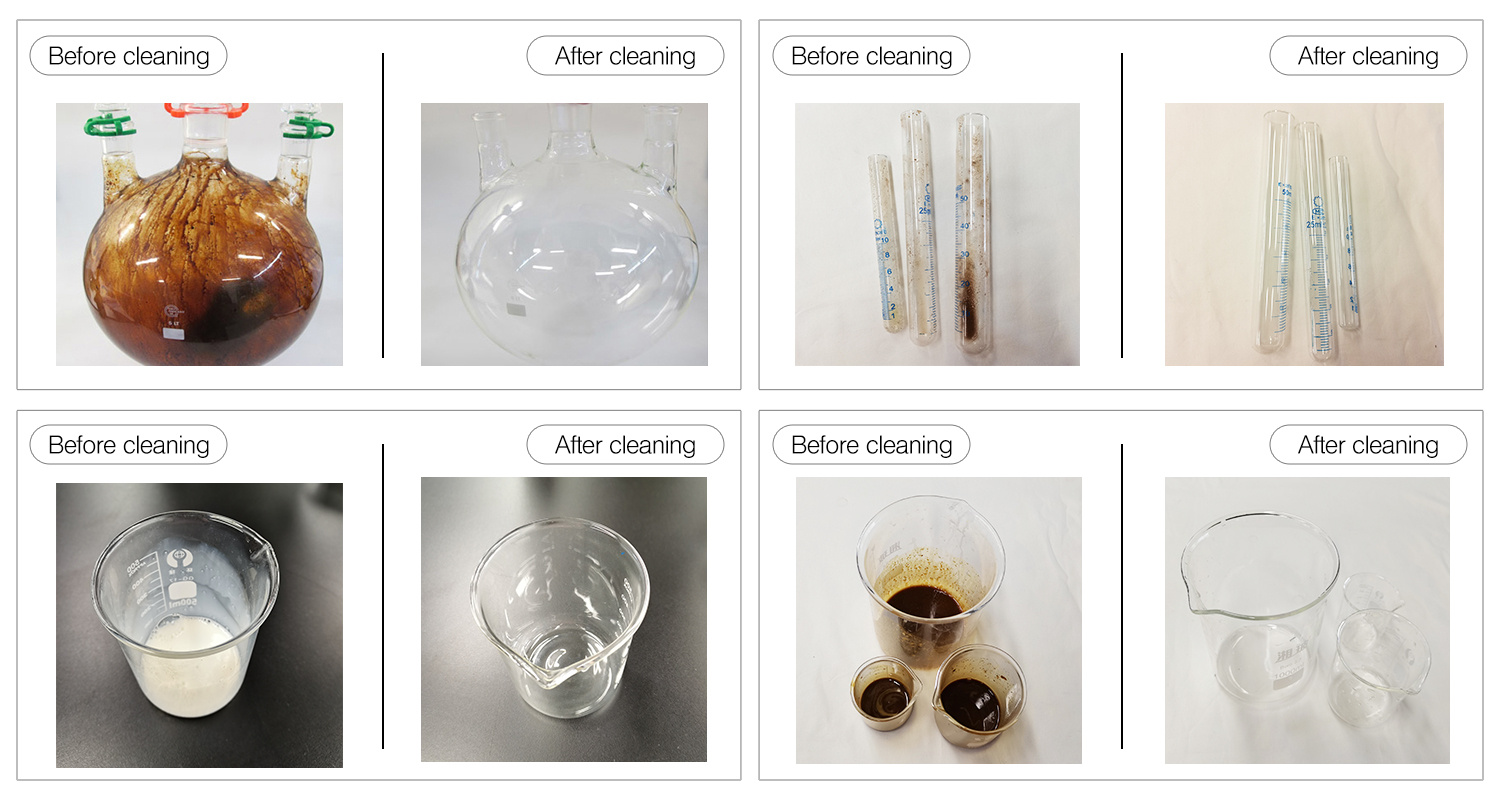

Cleaning laboratory glassware such as flasks, graduated cylinders, burettes and pipettes require careful handling to avoid breakage. Lab glassware of complex shape is also difficult to clean.

The Granbo GM1240W Ultrasonic Cleaner is professional cleaning equipment that can make your Glassware clean.

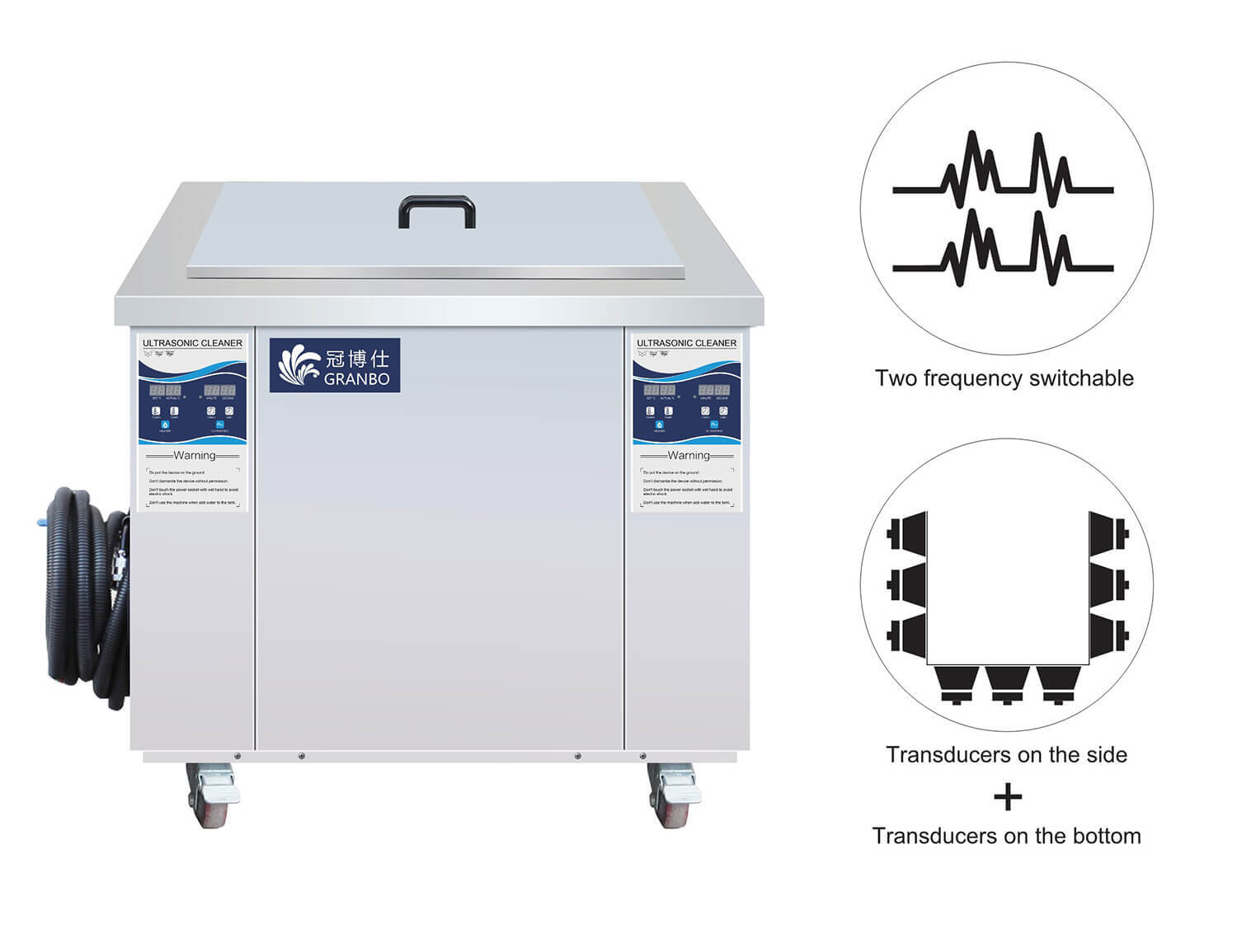

Dual Frequency

20-80℃

Power Adjustable

Dual Controller

Dual Frequency & Dual Controller With Bottom & Side Vibration Industrial Cleaning machine

Parameters

Function