Building an Industrial Ultrasonic Cleaner from Scratch

Browse Volume:128 Classify:Support

There’s something inherently satisfying about engineering a machine with your own hands—especially one as powerful and nuanced as an industrial ultrasonic cleaner. Whether you’re restoring carburetors, degreasing aerospace parts, or descaling medical equipment, ultrasonic cleaning delivers something traditional methods can’t: microscopic precision without abrasive damage. But can you actually build one yourself? The answer is yes—with the right knowledge, tools, and a bit of determination.

Understanding the Core Mechanism: What Makes Ultrasonic Cleaning Work

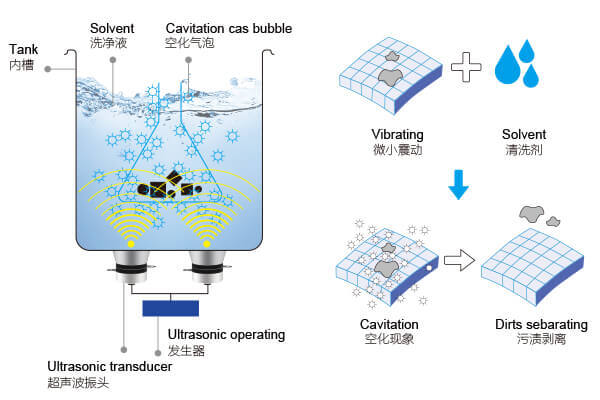

At the heart of ultrasonic cleaning lies a physical phenomenon known as cavitation. Imagine sound waves creating millions of microscopic bubbles in a liquid—these bubbles form and collapse with incredible force, loosening even the most stubborn grime from metal, glass, and plastic surfaces. For industrial-scale applications, this cavitation needs to be robust, uniform, and controllable across large volumes. That’s why the design process starts with choosing the right frequency (usually 25–80 kHz for industrial applications) and transducer type.

Most industrial cleaners use piezoelectric or magnetostrictive transducers bonded to the tank. The frequency you choose will define the cleaning effect: lower frequencies like 25 kHz generate larger bubbles and higher impact—great for heavy contaminants—while higher frequencies like 68 or 80 kHz are perfect for delicate components or precision optics.

The Principle Behind Ultrasonic Cleaning

Essential Components and Material Choices for a Durable System

A DIY industrial ultrasonic cleaner isn’t just a scaled-up version of a tabletop device. Every component, from the tank material to the transducer mounting method, needs careful planning. Start with a tank made of high-grade stainless steel—304 is a minimum, but 316L is often preferred in industrial settings for its resistance to corrosive chemicals.

Next, select transducers with reliable performance curves and robust adhesion methods. Epoxy-bonded transducers are common in DIY setups, though some advanced systems use welded or bolt-on designs for better long-term durability. You’ll also need a generator that matches the frequency and power output of your transducers. For industrial applications, look for at least 500–2000W of power, depending on the tank size.

And don’t forget heating. Many contaminants—like oils, greases, and carbon—clean far more efficiently at elevated temperatures. Integrating a thermostatically controlled heating system ensures consistent cleaning performance.

Control Systems and Power Management: Making It Safe and Smart

Building an industrial ultrasonic cleaner isn’t just about raw power—it’s about control. A machine that delivers thousands of microscopic shockwaves every second needs to be predictable, stable, and above all, safe. That’s where thoughtful design comes in.

First, think about how you’ll interact with the machine. A simple switch might work for a household device, but in industrial use, timed cycles, temperature regulation, and adjustable power settings aren’t luxuries—they’re essentials. Precision matters, whether you’re degreasing engine parts or cleaning circuit boards. Being able to fine-tune the intensity or duration of a cleaning session ensures you’re not overdoing it or leaving grime behind.

Just as important is managing electricity wisely. Ultrasonic cleaners typically draw significant current, and when water and electronics are working in close proximity, insulation and safety barriers become critical. Power lines should be shielded, circuits should have built-in fuses or breakers, and the whole system must be able to shut down instantly in case of overload or short-circuit. These aren’t “nice to have” features—they’re the difference between a dependable machine and a potential hazard.

For those with experience, building in responsive feedback—like temperature sensors or cleaning timers—adds another layer of intelligence. You start to feel like the machine isn’t just reacting, but listening. And that’s when cleaning performance truly becomes consistent.

But keep in mind: even the smartest control panel means little if the physical build is careless. Electrical connections must be dry and stable. Grounding must be solid. And nothing should be left to improvisation when power and water share a cabinet.

Ultimately, control isn’t just about buttons and dials—it’s about trust. The more intentional you are in designing how your ultrasonic cleaner behaves, the more confidently you’ll be able to use it, day after day.

Practical Assembly Tips and Mistakes to Avoid

When assembling your machine, start with electrical isolation in mind. Water and electricity are a dangerous duo, especially when working at industrial voltages. All connections should be moisture-proof, well-insulated, and tested thoroughly. Use industrial-grade silicone sealants around tank joints, and consider floating the tank on vibration-dampening rubber feet to reduce noise and mechanical wear.

Another tip: test your cleaning effectiveness with aluminum foil. Place a foil strip into the cleaning bath for 1–2 minutes. Uniform perforations indicate even cavitation. If you see large unperforated sections, your transducer placement or frequency might be off.

One common error? Oversizing the tank but undersupplying power. A huge tank with only a few hundred watts of ultrasonic energy will clean poorly. Conversely, too much power in a small tank can cause erosion or damage to delicate items.

When to Build and When to Buy: Knowing Your Limits

There’s a certain allure in building your own industrial ultrasonic cleaner—the control, the customization, the sense of accomplishment. For smaller-scale use or experimental setups, going the DIY route can be both cost-effective and educational. It allows you to explore the fundamentals of ultrasonic physics while tailoring the system to your unique needs.

But scaling up brings new challenges. When you’re dealing with frequent use, larger parts, or stringent cleanliness standards, even the most well-crafted DIY machine can fall short. That’s where professional systems start to show their value—not just in convenience, but in performance, durability, and peace of mind.

Take Granboultrasonic, for example—a manufacturer focused exclusively on industrial ultrasonic cleaning solutions. Their systems are designed around water-based, detergent-compatible processes that support both heavy-duty and precision cleaning. Whether you’re working with complex geometries like blind holes and honeycombs or need long bath life with anti-corrosion performance, their technology is engineered for reliability and consistency.

What sets them apart is their full-stack capability: from product design and manufacturing to branding and technical support, it’s all in-house. Their dedicated engineering team doesn’t just build ultrasonic machines—they understand the chemistry, the cleaning physics, and how to align those with specific industry applications. So if your needs are larger, more technical, or if uptime truly matters, choosing a professionally designed system might save you far more than it costs.

It comes down to a simple question: do you want to experiment, or do you need results—repeatable, scalable, and supported? Building is rewarding, but buying from a proven name like Granboultrasonic ensures you’re not compromising on quality where it counts most.

Granboultrasonic cleaners

Granbo Ultrasonic

Granbo Ultrasonic