Is It Safe to Clean Silver in an Ultrasonic Cleaner?

Browse Volume:50 Classify:Support

Before diving into whether ultrasonic cleaners are appropriate for silver, it’s essential to understand what silver actually is—and what makes it such a beloved yet temperamental material.

Silver has been used for centuries in everything from coins and cutlery to fine jewelry and religious artifacts. Its bright luster, malleability, and prestige make it one of the most sought-after metals in the world. But with beauty comes vulnerability. Silver, particularly in jewelry and household items, can tarnish, dull, or suffer surface degradation over time—often just from sitting out in the air.

Sterling Silver vs. Pure Silver

Not all silver is created equal. The silver used in most consumer products is rarely pure. Pure silver—technically referred to as fine silver—is 99.9% silver, but it is too soft for most practical applications. It scratches easily, bends with minimal pressure, and isn’t durable enough for everyday wear.

That’s why most silver items are made of sterling silver, which is 92.5% silver and 7.5% other metals, usually copper. This alloy increases the strength and durability of the item while retaining most of the brilliant shine that people associate with silver.

Unfortunately, this added copper also makes sterling silver more susceptible to oxidation. It’s not the silver itself that tarnishes—it’s the copper content reacting with sulfur in the air or from skin oils, cosmetics, and pollution.

Why Silver Tarnishes So Easily

Tarnish is a natural chemical reaction, not just a surface stain. When silver comes into contact with sulfur-containing gases (like hydrogen sulfide in the air), a thin layer of silver sulfide forms on the surface. This layer appears dull, yellow, brown, or even black, depending on its thickness and the environment.

Even handling your silver can speed up tarnishing. Skin oils, lotions, sweat, and cosmetics all contribute to the chemical reactions that degrade silver’s surface over time. Add in exposure to saltwater, chlorine, or air pollution, and your once-sparkling necklace or coin collection may darken surprisingly fast.

Some people assume that this discoloration means the silver is “dirty,” but tarnish isn’t traditional dirt—it’s a form of corrosion. That distinction matters when choosing how to clean it.

Delicate Design and Detailing

Another key challenge when cleaning silver—especially jewelry—is its often intricate craftsmanship. From engraved patterns and filigree to soldered joints and gemstone inlays, silver pieces are rarely uniform blocks of metal. These details not only trap grime but also introduce potential weak points.

Aggressive cleaning methods—whether manual or ultrasonic—can sometimes damage these vulnerable areas. High-frequency vibrations may loosen stones, rough brushes can remove intentional oxidation, and harsh chemicals can wear down solder or polish away subtle design elements.

This complexity means any cleaning solution or method must take into account both the metal and the craftsmanship. The wrong technique might brighten the surface—but destroy what makes the item special.

Traditional Methods of Cleaning Silver

Long before ultrasonic cleaners appeared in jewelry stores or homes, silver owners had to rely on manual techniques to restore shine and remove tarnish. Many of these traditional methods are still in use today—and for good reason. They’re accessible, relatively safe, and offer varying degrees of control, especially for items that are antique, delicate, or set with sensitive stones.

But no method is perfect. Each approach has its own strengths, limitations, and use cases. Understanding these classic techniques is key to appreciating when—and why—modern solutions like ultrasonic cleaning might be considered.

Polishing Cloths: Gentle and Reliable

Perhaps the most common method of silver maintenance is the use of silver polishing cloths. These are soft cloths treated with a mild abrasive compound designed to rub away tarnish without damaging the metal beneath.

For light tarnish, they work beautifully. A few swipes and the silver regains its familiar shine. They’re also great for touch-ups and regular maintenance—particularly on smooth surfaces like rings, bangles, or flatware.

However, polishing cloths have a major shortcoming: they can’t reach into tight crevices, filigree, or under-set stones. And if the tarnish is heavy or deeply embedded, hand-polishing becomes labor-intensive and slow. Worse, too much pressure in one area can cause uneven wear over time.

Silver Dips and Chemical Baths

Silver dips are liquid chemical solutions—often containing thiourea or sulfuric acid derivatives—designed to remove tarnish quickly and thoroughly. You simply dip the silver into the solution, wait a few seconds, and rinse.

These are incredibly effective for restoring high-shine finishes to silver chains, utensils, and plain surfaces. The transformation is nearly instant.

But there’s a dark side: silver dips can strip away intentional patinas, oxidized finishes, and fine detail. They may also corrode solder joints or cause pitting in soft areas if left too long. Chemical dips are especially risky for multi-material items, such as jewelry with glued stones, pearls, or enamel.

Additionally, many dips are toxic, difficult to dispose of, and not eco-friendly. They’re best used sparingly and with proper ventilation and gloves.

Homemade Cleaning Recipes

DIY enthusiasts have long promoted baking soda and aluminum foil methods. This approach involves lining a pan with foil, adding hot water and baking soda, and submerging the silver. A mild electrochemical reaction occurs, removing tarnish from the silver and transferring it to the foil.

It’s a clever and non-abrasive way to handle silver that’s badly tarnished but not delicate. It requires no scrubbing, and the reaction usually finishes in a minute or two.

Still, results can vary depending on water temperature, tarnish level, and item geometry. And again, this method isn’t suitable for items with glued stones, intentional oxidation, or mixed materials.

Other popular at-home options include toothpaste (abrasive and risky), lemon juice (acidic and corrosive), or vinegar (effective but smelly and sometimes harsh). While some people swear by these hacks, they can do more harm than good if misapplied.

The Limitations of Manual Cleaning

What all these methods share is a need for careful handling and time. Cleaning by hand can be soothing and satisfying, but it’s not always practical—especially for bulk jobs like polishing dozens of silver utensils, coin collections, or intricately designed jewelry sets.

Some details are just too small to reach. Some pieces are too fragile to rub. And some users simply don’t have the time or dexterity to keep up with regular polishing routines.

This is where ultrasonic cleaning starts to sound tempting—especially if it promises to do the job faster, more evenly, and with less effort. But is it the right choice for silver?

That’s the question we’ll explore next.

How Ultrasonic Cleaning Works

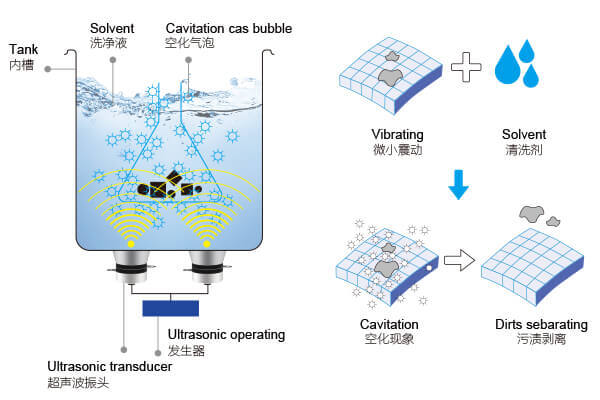

The concept of ultrasonic cleaning may seem futuristic, but it’s grounded in straightforward physics and engineering. At its core, this technology harnesses the power of high-frequency sound waves to clean surfaces—not through forceful abrasion or chemical reaction, but through a process known as cavitation.

This cleaning method is widely used in laboratories, dental clinics, repair workshops, and jewelry stores—especially for cleaning intricate or hard-to-reach areas. But understanding how ultrasonic cleaning actually works is critical to deciding whether it’s right for your silver items.

The Principle Behind Ultrasonic Cleaning

What Is Cavitation?

Cavitation occurs when ultrasonic frequencies (typically between 20 kHz and 80 kHz) are passed through a liquid—usually water or a water-based cleaning solution. The sound waves create rapid pressure fluctuations in the liquid, forming microscopic bubbles.

These bubbles aren’t filled with air—they’re tiny vacuums, rapidly forming and collapsing thousands of times per second. When they implode, they release small amounts of energy in the form of heat and pressure.

This doesn’t sound like much on a micro scale, but collectively, these bubble bursts scrub the surface of submerged items with surprising power. They dislodge dirt, oil, debris, and even oxidation without scratching or damaging the surface—assuming, of course, the material is compatible with the process.

Uniform Cleaning for Intricate Items

One of the biggest strengths of ultrasonic cleaning is its ability to reach places human hands and polishing cloths cannot. The cavitation bubbles form around every surface of the object, penetrating crevices, hinges, holes, and undercuts where grime often hides.

This is particularly valuable for items with fine engraving, filigree, or inner surfaces—like rings, necklaces, or silverware with hollow handles. Manual cleaning simply can’t match that level of reach.

What’s more, the cleaning is uniform. There’s no risk of over-polishing one area while neglecting another. It’s a full-body clean that often takes just minutes.

Ultrasonic Frequency and Power: What They Mean

Not all ultrasonic cleaners are the same. Some operate at 28 kHz (more aggressive, better for removing heavy grime), while others use 40 kHz or even 80 kHz for gentler, more precise cleaning.

Higher frequencies produce smaller cavitation bubbles, which are less forceful but better suited for fragile items and fine particles. Lower frequencies create larger, more energetic bubbles that can remove stubborn deposits—but also carry more risk of surface damage.

The power (measured in watts) also affects the intensity of the cleaning. Too much power on soft or oxidized silver may cause pitting or loss of finish, especially if left in the tank for too long.

This is why understanding your item’s material, construction, and condition is critical before dropping it into an ultrasonic bath.

Cleaning Solutions Enhance the Effect

Ultrasonic cleaning alone—just with water—can work, but it’s rarely effective enough for oily or tarnished items. That’s why most ultrasonic cleaners require the use of specially formulated cleaning solutions.

These solutions reduce surface tension, improve cavitation efficiency, and help dissolve specific types of contaminants, such as grease, dust, polishing residue, or oxidation. We’ll explore in more detail later why dish soap isn’t a good alternative and why specialized solutions matter.

But for now, what matters is this: ultrasonic cleaning is not magic. It’s a powerful method—but only when used with the right frequency, cleaning solution, and timing.

Granbo Ultrasonic Jewelry Cleaning

Now that we understand how ultrasonic cleaners work, let’s address the big question: can you safely clean silver with one—and what should you watch out for?

Can You Clean Silver with an Ultrasonic Cleaner?

Now that we understand the mechanics behind ultrasonic cleaning, it’s time to focus on the real question: Is silver a safe candidate for this method? The answer, as with most things involving precious metals, depends on several factors—chief among them being the type of silver, the extent of tarnish, and whether other materials are present.

Ultrasonic cleaning can be effective for silver, but it isn’t without caveats. While many jewelers and restoration professionals use ultrasonic cleaners to brighten silver items, using this technology blindly could cause more harm than good.

Pure and Sterling Silver: Compatible, with Caution

From a material standpoint, both pure silver and sterling silver are technically safe to be cleaned ultrasonically—especially if they are solid pieces without embellishments. The ultrasonic vibrations won’t melt or warp the metal. In fact, silver’s density and hardness allow it to handle ultrasonic frequencies reasonably well, especially at 40kHz or higher.

The real risk comes not from the ultrasonic process itself, but from secondary factors, including:

- The presence of oxidized finishes, which can be unintentionally stripped.

- The use of harsh solutions that may react chemically with silver or its alloyed metals.

- The presence of solder joints or soft components, which may weaken or degrade.

The biggest risk for sterling silver, which includes 7.5% copper, is surface pitting. If a highly alkaline or acidic solution is used—or if cavitation is too aggressive—microscopic holes can develop on the surface. This is especially common in older or already-tarnished items.

Silver-Plated Items: Not Recommended

While solid silver items may survive ultrasonic cleaning with minimal issues, silver-plated items are a different story. These products consist of a base metal (often brass or nickel) coated with a very thin layer of silver.

Ultrasonic vibration can cause the plating to peel, flake, or wear off entirely, especially along edges or engraved areas. Additionally, any pitting or tarnish in the base layer can accelerate degradation once the plate is breached.

If you’re not sure whether an item is plated or solid, it’s best to avoid ultrasonic cleaning unless you’ve confirmed the material and construction.

Gemstones and Inlays in Silver Jewelry

Silver jewelry often features embedded stones—turquoise, opals, pearls, or even glue-set diamonds. This is where ultrasonic cleaning becomes particularly dangerous.

Many natural stones, especially porous ones like opal, turquoise, lapis, or onyx, cannot withstand ultrasonic vibrations. They may crack, fade, or become dislodged entirely. Similarly, if the stone is attached with adhesive instead of prongs, ultrasonic agitation can weaken the bond.

Even hard stones like diamonds and sapphires can present a risk if the silver setting is fragile or if the piece includes multiple materials (such as enamel or resin).

In short: Do not place multi-material silver jewelry in an ultrasonic cleaner unless you’re absolutely certain the stones, adhesives, and coatings are compatible.

Pre-Check for Loose Components

Even if the item is solid sterling silver and free of embellishments, it’s crucial to inspect it before ultrasonic cleaning. Over time, joints, chains, clasps, and solder points can become weakened through normal wear.

The intense vibration of an ultrasonic bath can cause tiny cracks to expand or delicate links to break, especially on antique items. A pre-check can prevent a minor repair issue from turning into a complete breakage.

Benefits of Using Ultrasonic Cleaners for Silver (When Used Properly)

Despite the caveats and risks discussed earlier, ultrasonic cleaners can offer excellent benefits when used appropriately with silver items. In controlled settings—where the right frequency, solution, and exposure time are used—these machines offer a cleaning quality that is almost impossible to achieve through manual methods alone.

Let’s explore the primary advantages of ultrasonic cleaning for silver when done under the right conditions.

Deep Cleaning in Intricate Areas

One of the greatest frustrations when cleaning silver is reaching tight crevices, ornate engravings, and intricate filigree. Polishing cloths, cotton swabs, and brushes often can’t access these tiny areas. Tarnish and grime tend to accumulate in these recesses, dulling the entire appearance of the piece.

Ultrasonic cavitation reaches every exposed surface, no matter how small. The imploding microbubbles generated during the process form around the item and penetrate even the most detailed patterns. For antique silver, religious artifacts, or highly decorative jewelry, this can be a game-changer.

Uniform Results Without Manual Scrubbing

When polishing by hand, it’s easy to focus on one spot more than another. This leads to uneven finishes and over time, excessive thinning of silver in certain areas—especially corners and edges.

Ultrasonic cleaning solves this problem by cleaning all surfaces evenly and simultaneously. There’s no risk of human error or inconsistency. The final result is a uniform, revitalized shine that looks more professional and less patchy.

Time-Saving and Convenient

Polishing silver by hand takes time, especially for heavily tarnished items. And if you’re dealing with a collection of silverware, jewelry, or coins, the task becomes exhausting.

Ultrasonic cleaners dramatically reduce the time required. In many cases, five to ten minutes in the bath can produce results that would otherwise take hours. And because it’s a hands-off process, you can clean multiple items at once while doing something else.

This makes ultrasonic cleaning especially useful for:

- Jewelry stores that process dozens of pieces daily

- Silver collectors looking to maintain a large inventory

- Labs or dental clinics with silver-based tools that require sanitation and shine

Gentle on Structure (If Settings Are Correct)

When set to the correct frequency (usually 40kHz or higher for delicate items), ultrasonic cleaning is remarkably gentle on structural integrity. There’s no scratching, no scuffing, and no pressure applied by hand.

That makes it a safer alternative than abrasive toothpaste or chemical dips—especially for items with light tarnish or embedded grime rather than deep oxidation.

Eco-Friendly Potential

While some ultrasonic solutions contain surfactants and solvents, many non-toxic, biodegradable formulas are available. And because the process is mechanical rather than chemical, less solution is needed compared to dip-style methods.

If you use a water-based ultrasonic detergent formulated for silver, the process becomes significantly more environmentally friendly, particularly when compared with disposable polishing pads or strong chemical dips that require hazardous waste disposal.

Risks and Limitations of Ultrasonic Cleaning for Silver

While ultrasonic cleaning can be incredibly effective under the right conditions, it’s not without its drawbacks. In fact, when misapplied, this method can cause irreversible damage to silver pieces—especially those with delicate construction, surface treatments, or non-silver components.

To fully understand whether ultrasonic cleaning is the best option for your silver, you need to weigh its potential downsides as carefully as its benefits.

1. Surface Pitting from Prolonged Exposure

The same cavitation process that removes dirt and tarnish can, if left unchecked, begin to erode the silver’s surface. This is particularly true for sterling silver, which includes a percentage of copper.

When the ultrasonic cleaner is set to a lower frequency (such as 28kHz), the energy released during bubble implosion is more intense. Over time, this can create microscopic pits or soft spots on the metal, dulling its appearance and compromising its strength.

Even at higher frequencies, leaving silver in the bath too long—or using too strong a cleaning solution—can result in matte patches or discoloration, especially on antique pieces.

2. Damage to Oxidized and Patina Finishes

Some silver items are intentionally oxidized to create contrast and artistic definition. This darkened finish is often used in designer jewelry or vintage-inspired flatware to bring out depth in engravings or textures.

Ultrasonic cleaners don’t discriminate between intentional and unintentional oxidation. The cavitation process, particularly when used with detergents, can strip away patinas, leaving the piece unnaturally bright and eliminating its visual character.

For items that rely on oxidized surfaces as part of their design, ultrasonic cleaning is usually not recommended.

3. Incompatibility with Non-Silver Components

As mentioned in the previous section, silver items frequently incorporate other materials—pearls, adhesives, stones, wood, resins, or enamel. These components are often less stable under ultrasonic agitation.

- Soft gemstones can fracture or become cloudy.

- Glue joints can weaken or dissolve.

- Enamel may chip or flake.

- Wood inlays can absorb moisture and warp.

Unless the item is made entirely of solid silver and has no embedded parts or coatings, ultrasonic cleaning carries a high risk of collateral damage.

4. Hidden Cracks and Soldered Joints

Even when a silver item looks intact to the naked eye, it may contain microfractures or worn-out solder joints from years of wear. Ultrasonic vibration can amplify these weaknesses, causing tiny flaws to grow into visible breaks.

This is particularly problematic for antique silver jewelry or heirloom pieces, where the structural integrity may already be compromised.

Pre-inspection is critical—especially if the piece holds sentimental or financial value. In many cases, a soft cloth and gentle polish may be the safer route.

5. False Sense of Security

Because ultrasonic cleaners seem like advanced, professional-grade tools, they can create a false sense of safety. Owners may assume that “if jewelers use it, it must be fine for everything.”

In reality, even professionals often avoid ultrasonic cleaning for certain silver items unless absolutely necessary. Jewelers typically test individual items, use lower power settings, limit exposure time, and select compatible solutions.

For untrained users at home, relying too heavily on ultrasonic cleaning without understanding its limitations and proper configurations can result in avoidable damage.

Why Specialized Solutions Are Essential for Silver

The performance and safety of ultrasonic cleaning are not just about the machine itself. The cleaning solution you use plays a central role in determining whether the silver is restored to a brilliant shine—or left dulled, pitted, or even damaged. This is where the importance of using the right solution becomes crystal clear.

So, why can’t you just use regular dishwashing liquid or household cleaners in your ultrasonic bath? Let’s dig into the science and practicality behind specialized cleaning formulas.

The Problem with Dishwashing Detergents

On the surface, dishwashing liquids seem like a mild and accessible choice. They clean grease, don’t feel harsh to the touch, and are marketed as “gentle.” However, these products are formulated for use on glass, ceramic, and cookware—not precious metals like silver.

Dishwashing soaps can pose several risks in an ultrasonic environment:

- Foaming and bubble buildup: Most household soaps contain surfactants that create foam. In an ultrasonic tank, foam disrupts the cavitation process, making cleaning less effective and uneven.

- Chemical residues: Many dish soaps contain fragrances, dyes, or brighteners. These additives can react with silver, especially sterling silver, leaving behind a film or causing long-term discoloration.

- Unknown pH levels: Some dishwashing liquids are slightly alkaline or acidic. Over time, this can accelerate corrosion or tarnish in silver alloys.

Because ultrasonic cavitation amplifies the interaction between the solution and the item being cleaned, any inappropriate chemical becomes more aggressive, increasing the likelihood of surface damage.

What Makes a Solution “Ultrasonic-Safe” for Silver?

Specialized ultrasonic cleaning solutions are scientifically engineered to balance cleaning power with material safety. For silver, this usually means:

- Neutral to mildly alkaline pH (around 7–9)

- Non-foaming surfactants

- Chelating agents that lift tarnish without scratching

- Anti-tarnish inhibitors that help preserve the shine after cleaning

- Biodegradable and rinse-free ingredients

These formulas are designed to enhance cavitation rather than interfere with it, ensuring better contact with the silver surface while being gentle enough to avoid stripping finishes or causing pitting.

Types of Silver-Safe Solutions

Depending on the brand and intended use, silver-compatible ultrasonic cleaners may be labeled as:

- Silver cleaning concentrates (diluted in water before use)

- Multi-metal cleaners (safe for both silver and gold)

- Jewelry cleaning solutions (check labels carefully—some may exclude silver-plated items)

- Enzymatic solutions (more common in medical or lab settings, but some are silver-safe)

Always look for explicit confirmation on the label that the formula is safe for sterling silver or solid silver pieces. When in doubt, consult the manufacturer or choose a product formulated specifically for jewelry.

Silver jewelry cleaning

Homemade Solutions: Can You DIY It Safely?

Some users prefer to mix their own silver-cleaning solution at home using ingredients like baking soda, mild soap, or ammonia-free glass cleaner. While there are some safe combinations, homemade solutions can be unpredictable in ultrasonic conditions.

For example:

- Baking soda may leave gritty residues that cause micro-abrasions.

- Vinegar-based solutions are too acidic and can etch silver surfaces.

- Ammonia and bleach should never be used with silver in any setting.

If you do go the DIY route, be cautious. A simple mix of warm distilled water and a few drops of mild, ammonia-free dish soap (formulated without surfactants or dyes) is your safest bet. However, even then, it’s not a match for a professionally formulated solution that’s lab-tested for ultrasonic compatibility.

Best Practices When Cleaning Silver with Ultrasonic Cleaners

Once you’ve decided to clean your silver using an ultrasonic cleaner—and you’ve selected a proper, silver-safe cleaning solution—the next step is learning how to do it properly. Technique matters. Even the best equipment and the most compatible solution can cause damage if you’re not careful.

To help ensure a safe and effective cleaning session, here are the most important best practices to follow when working with silver in an ultrasonic cleaner.

Inspect Each Item Before Cleaning

Always begin by carefully inspecting your silver item under good lighting. Look for:

- Cracks or stress marks in the metal

- Loose joints, clasps, or settings

- Attached components made from non-silver materials (e.g., enamel, wood, stones, pearls)

If the item shows signs of fragility or has delicate inlays, it’s best to clean it manually or consult a professional jeweler. Ultrasonic cleaners can exacerbate existing weaknesses.

Choose the Right Frequency

Ultrasonic cleaners vary in frequency. For silver, the ideal range is usually:

- 40 kHz or higher for delicate silver jewelry or antique items

- 28 kHz for more durable items or those with thicker tarnish layers (used cautiously)

Lower frequencies generate more aggressive cavitation bubbles, which are useful for removing stubborn grime but can harm soft or aged surfaces. Higher frequencies are gentler, producing smaller bubbles that clean finely without much abrasion.

For most silver household items, 40–45 kHz offers the best balance of cleaning power and safety.

Use a Properly Diluted, Silver-Safe Solution

Follow the dilution instructions precisely. Using a concentrated solution can increase the chemical aggressiveness, while under-dosing can reduce cleaning effectiveness. Silver-cleaning solutions usually require a ratio of 1:10 to 1:20 with water, depending on brand and concentration.

Always mix the solution before placing your silver item inside the tank, and never add solution directly onto the silver—this helps ensure even coverage.

Warm Water is Better—But Not Hot

Ultrasonic cleaners often come with built-in heaters. For silver, use warm water around 40–50°C (104–122°F). Hot water may speed up cleaning, but it also increases the chances of surface dulling or tarnish redeposition.

Avoid boiling temperatures and always allow the machine to stabilize at the correct temperature before starting.

Use a Basket or Suspension Tool

Never place silver items directly on the bottom of the ultrasonic tank. This creates metal-on-metal contact and disrupts cavitation. Use the machine’s built-in mesh basket or suspend the item using non-metallic supports.

Proper positioning also ensures that bubbles form around the object instead of being blocked by surfaces below.

Limit Cleaning Time

Silver doesn’t need long cycles in ultrasonic baths. For lightly tarnished or oily items:

- 3 to 5 minutes is typically enough

For moderate tarnish:

- 6 to 8 minutes

If you need to clean beyond 10 minutes, allow the item to rest and cool between cycles. Extended exposure, even at safe frequencies, can stress the metal over time.

Rinse and Dry Immediately

After cleaning, remove your silver piece and rinse it thoroughly in clean, distilled water to eliminate all solution residue. Tap water can contain minerals that cause new tarnish to form.

Dry gently with a soft microfiber cloth. Avoid air-drying, which can leave water spots or encourage surface oxidation.

Polish If Desired (Optional)

If your item was especially dull or oxidized, you might wish to follow up with a silver polishing cloth to enhance its shine. However, if the ultrasonic process restored the item’s luster, polishing may not be necessary.

Be careful with commercial silver polishes—some are abrasive or leave films that degrade over time.

When to Avoid Ultrasonic Cleaning for Silver Entirely

Despite the many benefits ultrasonic cleaners offer for silver, there are still scenarios where using this technology is not recommended. In fact, for certain types of silver items, ultrasonic cleaning can cause irreversible damage—both physically and in terms of value.

Let’s walk through the conditions where ultrasonic cleaning should be avoided altogether, and why opting for alternative cleaning methods is the smarter, safer route.

1. Antique or Heirloom Silver

Antique silver pieces often feature delicate craftsmanship, soldered joints, and aged patinas that are valuable precisely because of their age. The intense vibrations of an ultrasonic cleaner—especially at lower frequencies—can loosen joints, dislodge fragile elements, or even crack hairline fractures that have developed over time.

Additionally, the cleaning process may strip away intentional oxidation or finishes that give antique silver its character and value.

If you’re unsure whether your silver is antique or just looks old, consult with a jeweler before placing it in an ultrasonic bath.

2. Silver-Plated Items

Silver-plated items are typically made by depositing a thin layer of silver onto a base metal like copper or brass. While they may look identical to sterling silver at first glance, the surface is far more vulnerable to ultrasonic cavitation.

Aggressive cavitation can:

- Erode the silver layer, exposing the base metal beneath

- Cause bubbling or peeling of the plate

- Trigger galvanic corrosion, especially if multiple metals are cleaned simultaneously

Silver-plated items are best cleaned manually using mild solutions and soft cloths.

3. Pieces with Porous or Organic Inlays

Many silver items—particularly jewelry—include decorative inlays made of:

- Pearls

- Amber

- Wood

- Shell

- Coral

- Resins or plastics

These materials are either too soft, too porous, or too chemically reactive to withstand ultrasonic cleaning. They may absorb water, discolor, or crack under the influence of temperature and vibration.

Even if the silver portion of the item would benefit from ultrasonic cleaning, the presence of these inlays means it should be excluded from the bath entirely.

4. Items with Loose Stones or Fragile Settings

Ultrasonic cleaning can cause stones to become dislodged if their prongs or bezels are loose. While this issue applies more broadly to all types of jewelry, it is especially important with silver items, which often have softer settings than gold or platinum equivalents.

You may not notice a loose stone until it has already fallen out—either inside the tank or later during wear.

Perform a “tap test” before cleaning: gently tap the item near your ear. If you hear any rattling or movement, skip ultrasonic cleaning.

5. Hollow, Sealed, or Composite Silver Items

If a silver item is hollow (e.g., bangles, flasks, or decorative spheres) or sealed with glue, resin, or wax, ultrasonic cavitation can:

- Break internal seals

- Cause implosion or collapse of thin walls

- Force water into air pockets that can’t easily dry

Water intrusion can lead to mildew, corrosion, or long-term structural weakening. The risk simply isn’t worth it for these items.

Alternatives to Ultrasonic Cleaning for Sensitive Silver Items

If you’ve determined that your silver piece isn’t suited for ultrasonic cleaning, don’t worry—there are still highly effective and gentle alternatives that can restore shine, remove tarnish, and preserve the integrity of your item. These methods rely on manual care, often using ingredients or tools already available at home, or solutions specifically made for silver preservation.

Let’s explore a few safe and proven approaches to cleaning delicate or antique silver.

1. Silver Polishing Cloths

Silver polishing cloths are specially treated with tarnish-removing compounds. They work through light abrasion and chemical reaction, making them ideal for removing tarnish from:

- Jewelry

- Cutlery

- Decorative items

- Antique silver with patinas

Because they don’t require moisture or soaking, polishing cloths are especially good for sensitive surfaces. They allow you to control the amount of pressure, avoid delicate areas, and retain oxidized details intentionally designed into the item.

Avoid using regular microfiber or cotton cloths not made for silver, as they may scratch the surface without effectively removing tarnish.

2. Mild Soap and Warm Water

This method is often overlooked, but for general dirt, fingerprints, or surface oils, a gentle dish soap and lukewarm water are usually enough. The key steps:

- Mix a few drops of mild, phosphate-free dish soap into a bowl of warm water.

- Soak the item briefly (1–2 minutes).

- Use a soft toothbrush to gently clean crevices and textures.

- Rinse thoroughly with distilled water.

- Pat dry with a soft cloth.

This approach is especially safe for silver-plated items, as it avoids aggressive chemical or mechanical actions.

However, it won’t remove deep tarnish—that’s where polishing or commercial cleaners come in.

3. Commercial Silver Dips and Creams

There are specially formulated dips and creams designed to dissolve tarnish through chemical reaction. These products are typically safe for most silver when used as directed.

- Silver dips work quickly (in seconds), making them suitable for uniform surfaces or chain links.

- Silver creams allow for targeted application, ideal for preserving patterns or patinas.

However, use caution:

- Never use dips on silver items with glued stones or hollow interiors.

- Always rinse thoroughly after use to neutralize chemical residues.

Choose reputable, well-reviewed brands and follow instructions precisely.

4. Baking Soda and Aluminum Foil Method

This popular DIY approach relies on a simple electrochemical reaction to lift tarnish from silver surfaces without scrubbing.

Steps:

- Line a glass or ceramic bowl with aluminum foil (shiny side up).

- Place the silver items on the foil.

- Sprinkle 1–2 tablespoons of baking soda and a pinch of salt over the items.

- Pour boiling water until items are submerged.

- Let sit for 2–5 minutes as the tarnish transfers to the foil.

- Rinse and dry thoroughly.

This method works well for heavily tarnished silver and does not rely on abrasion. However, it can strip away oxidized finishes or antique patinas, so use with caution on heirloom items.

5. Professional Cleaning

If your item is particularly valuable, sentimental, or complex in design, the safest option is to bring it to a professional jeweler or silversmith. They will:

- Evaluate the item’s condition

- Choose the correct cleaning method

- Protect structural integrity during the process

Professional cleaning is also a good opportunity to inspect for loose stones, broken clasps, or hidden damage before wear.

Expert Opinions on Ultrasonic Silver Cleaning from the Field

To bring balance to the discussion, let’s hear what professionals have to say about using ultrasonic cleaners for silver. From jewelry conservators to ultrasonic equipment manufacturers, these insights help illustrate both the promise and the pitfalls of this popular cleaning method.

What Jewelers Say

Many jewelers appreciate the convenience and efficiency of ultrasonic cleaners—but with caveats.

Brian Gavin, a fifth-generation jeweler and founder of Brian Gavin Diamonds, notes:

“Ultrasonic cleaners can work wonders for plain silver pieces, especially chains and rings without stones. But for mixed-metal pieces or items with any kind of adhesive, it’s better to avoid ultrasonic cleaning unless you’re absolutely sure how it’s constructed.”

Others echo this sentiment, emphasizing that when in doubt, opt for manual cleaning. Especially with heirloom jewelry or antique silver, ultrasonic methods should only be used by professionals familiar with the item’s build quality.

What Equipment Manufacturers Recommend

Ultrasonic cleaning equipment manufacturers typically provide detailed user guides outlining which materials are compatible with their devices. Most include silver as a compatible metal—provided that users follow these precautions:

- Use frequency settings at or above 40 kHz

- Avoid prolonged exposure beyond 10 minutes

- Use only non-ammoniated, non-acidic solutions

- Do not clean silver-plated items unless specified as safe

These guidelines align with what most jewelers recommend—cautious and informed use is key to success.

Conservators and Museum Professionals Weigh In

Institutions that manage historical artifacts tend to take a more conservative stance. According to The Canadian Conservation Institute (CCI), ultrasonic cleaning is not recommended for silver artifacts, especially those with cultural or historical significance. They emphasize the potential for damage due to:

- Cavitation-induced micro-pitting

- Disruption of solder joints or adhesives

- Loss of surface patinas or maker’s marks

Their stance reinforces the idea that ultrasonic cleaning is not one-size-fits-all—while it works well for commercial silverware or robust modern pieces, it’s not appropriate for everything.

Gemological Institute of America (GIA) Guidelines

Though not focused on silver exclusively, the GIA provides relevant guidance regarding ultrasonic cleaning. They recommend avoiding ultrasonic methods for any jewelry with:

- Organic or porous stones (like opals or pearls)

- Surface treatments

- Inclusions or fractures visible to the naked eye

Since many silver pieces include such components, GIA’s guidelines act as a reminder to analyze the entire item, not just its metal.

Professional Cleaners and Watchmakers

In industries where ultrasonic cleaning is routine—like watchmaking or dental tool maintenance—professionals emphasize the importance of material compatibility and proper calibration. Silver is generally treated with respect due to its softness and tendency to oxidize under chemical stress.

Professional cleaners often test the solution and timing on a single piece before placing an entire batch in the tank, a practice worth adopting for home users too.

Final Thoughts on Silver Cleaning and Responsible Use of Ultrasonic Cleaners

Ultrasonic cleaning is undeniably one of the most advanced and effective methods available for cleaning silver—but it’s not a magic bullet. Its benefits are substantial: deep cleaning in hard-to-reach places, minimal manual effort, and faster turnaround. Yet those same benefits can come at a cost if you don’t understand the limitations and requirements that come with ultrasonic technology.

Ultimately, the key to safe ultrasonic cleaning is knowledge. Knowing the composition of your silver item, selecting the right frequency and cleaning solution, and avoiding incompatible materials are all essential steps. It’s also important to remember that ultrasonic cleaners are best used strategically, not indiscriminately. Just because a cleaner can handle silver doesn’t mean every silver item should be placed in the tank.

If you’re unsure about a piece—whether it’s an antique, silver-plated, or adorned with glued-in stones—err on the side of caution. Use manual methods like polishing cloths or professional cleaning services. For modern, solid silver jewelry or flatware, ultrasonic cleaning can be a reliable and repeatable solution when done properly.

By combining smart cleaning practices with high-quality solutions, users can enjoy the long-term shine and beauty of silver without the risk of damage. Silver, after all, is not just a material—it often carries sentimental or financial value. Treating it with care ensures that it stays brilliant for years, or even generations, to come.

Granbo Ultrasonic Jewelry Cleaning Effect

Granbo Ultrasonic

Granbo Ultrasonic