Ultrasonic industrial cleaner for cleaning large ball bearings supporting customization

Browse Volume:911 Classify:Support

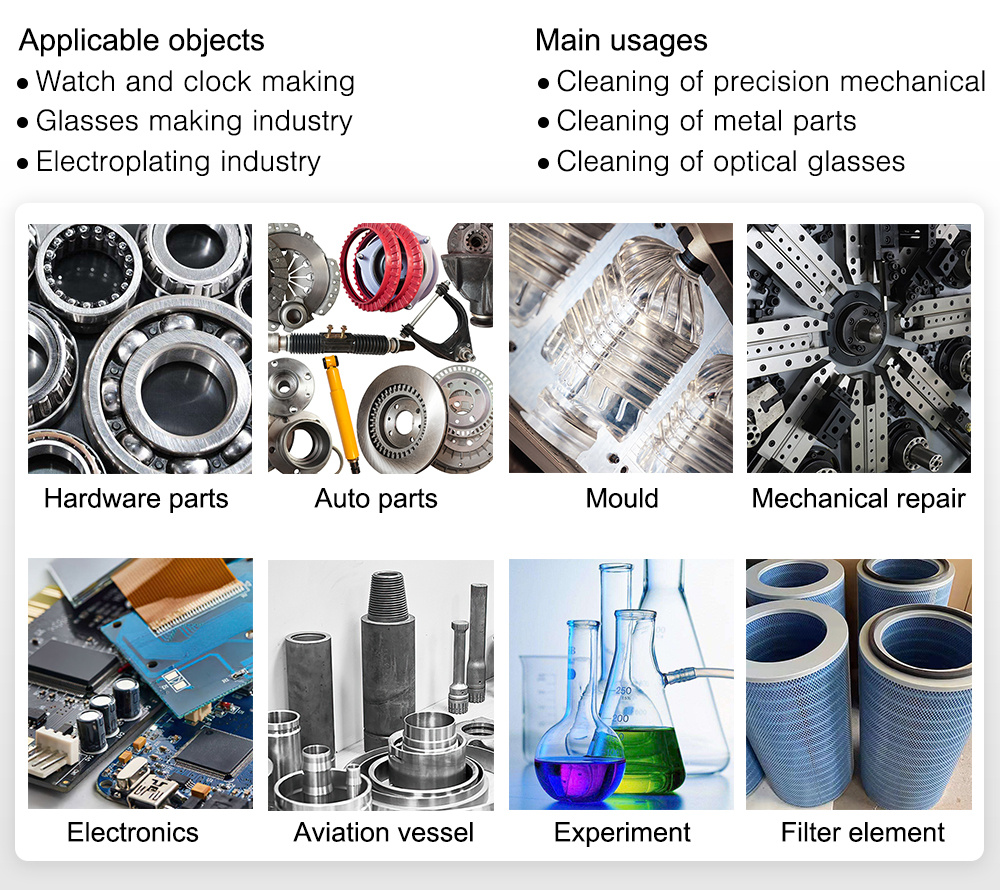

Ultrasonic industrial cleaner is a device that uses ultrasonic technology for cleaning, widely used in the industrial field, including cleaning various components and equipment. For cleaning large ball bearings, ultrasonic industrial cleaners can also provide effective solutions.

Ultrasonic cleaners generate high-frequency acoustic vibrations in the cleaning solution, generating small bubbles that quickly rupture, resulting in aggressive impact and eddy currents that separate and dissolve dirt and oil from the surface of ball bearings. This cleaning method can penetrate into the small pores and complex structures of ball bearings, thoroughly removing dirt while avoiding damage to the bearing surface caused by physical scraping.

Customized ultrasonic industrial cleaners can be designed and manufactured based on the size, shape, and specific requirements of ball bearings. Key customization factors may include the size, operating frequency, power, and cleaning fluid circulation method of the washer. This ensures that the washer can adapt to the size of the ball bearing and provide the best cleaning effect.

If you need to customize an ultrasonic industrial cleaner to clean large ball bearings, it is recommended to contact a professional cleaning equipment manufacturer or supplier to provide detailed information on your needs and requirements. They will be able to provide you with customized solutions and ensure that the washers meet your specific needs.

So the question arises, how many hertz frequencies should be chosen for ultrasonic industrial cleaning machines to clean heavy oil stains? What is the difference between 28kHz and 40kHz?

When selecting the frequency of ultrasonic industrial cleaning machines, it is necessary to consider the characteristics and cleaning requirements of the heavy oil stains to be cleaned. Generally speaking, lower frequency ultrasound (such as 28kHz) is suitable for cleaning heavier oil stains, while higher frequency ultrasound (such as 40kHz) is suitable for cleaning lighter and finer oil stains.

The ultrasonic frequency of 28kHz generates large bubbles and eddies during the cleaning process, which can provide strong cleaning and impact forces. This frequency is suitable for cleaning viscous, heavy oil stains that adhere to the surface, and can better penetrate and decompose this type of oil stain.

The ultrasonic frequency of 40kHz generates smaller bubbles and eddies, resulting in relatively light cleaning force. It is suitable for cleaning small and easily flowing oil stains, and is more suitable for applications with mild pollution or requiring a more gentle cleaning process.

Therefore, choosing a frequency of 28kHz or 40kHz depends on the viscosity, adhesion, and cleaning requirements of heavy oil stains. If the oil is heavy and difficult to clean, a frequency of 28kHz may be more suitable. If the oil stain is light or requires gentle cleaning, a frequency of 40kHz may be more suitable.

It is important to understand that the frequency of cleaning equipment is only one aspect of selection, and other factors such as power, cleaning fluid, cleaning time, and temperature also need to be comprehensively considered. The selection of the optimal frequency may require testing and adjustment in practical applications to achieve the best cleaning effect.

The above is the knowledge about cleaning large ball bearings with ultrasonic industrial washers. For more information, please consult us, Don’t Hesitate!

Granbo Ultrasonic

Granbo Ultrasonic

Hello!