Cleaning Ceramic Inserts the Right Way with Ultrasonic Power

Browse Volume:123 Classify:Support

Ceramic inserts are a workhorse in modern machining—tough, precise, and built to handle extremes. Whether they’re used in cutting tools, aerospace parts, or industrial molds, these tiny yet critical components don’t just demand performance—they demand precision maintenance too. And that’s where ultrasonic cleaning systems enter the scene. But here’s the twist: cleaning ceramic inserts isn’t as simple as dropping them into a bath and pressing start.

These inserts may look impervious, but in reality, their engineered surfaces—especially those with coatings like TiN, Al₂O₃, or CBN—require a cleaning process that removes contaminants without introducing microdamage. Ultrasonic cleaning, done right, can reach into every micron-level pit and groove. Done wrong, and you might just be quietly dulling the very edges that make them valuable.

Why Ceramic Inserts Need Special Cleaning Attention

It’s easy to think of ceramics as indestructible. After all, these inserts withstand the pressures of high-speed machining and endure temperatures that would warp metal. But what many forget is that ceramic’s high hardness often comes with brittleness, especially at sharp edges or where microcracks might have developed during use. Ultrasonic cavitation—the microscopic implosions that power the cleaning action—can either be your best friend or your worst enemy depending on how it’s applied.

Unlike oily metal parts or dusty components, ceramic inserts typically collect metallic debris, coolant residues, and microscopic particles from the workpiece. If left uncleaned, these contaminants can affect tool precision, accelerate wear, or even lead to failure under load. Traditional hand cleaning can’t reach the porous structure or ultra-fine details. Ultrasonic waves, on the other hand, can.

But the method must be tailored. Everything from frequency to temperature and cleaning fluid composition plays a part in protecting the structural integrity of the ceramic.

Cleaning ceramics

Setting the Right Ultrasonic Parameters for Ceramic Materials

The first golden rule is frequency. For most ceramic inserts—especially coated or edge-sensitive types—a mid-to-high frequency range is preferred. Frequencies around 40–68 kHz offer a gentler cavitation effect that cleans thoroughly without aggressive erosion. Lower frequencies (25–28 kHz), while effective for heavily soiled metal parts, are often too harsh for ceramics and may chip edges or cause fatigue on coated layers.

Temperature also matters. While ceramic materials are heat-resistant, the bonding agents in coatings or any residual coolant oils on their surface may react differently at higher temperatures. A safe range lies between 40°C and 60°C—warm enough to boost detergent activity, but not hot enough to risk structural stress.

Cleaning time should be optimized, not maximized. For most ceramic inserts, 5 to 10 minutes is sufficient, assuming the solution is properly mixed and the power density is consistent across the bath. Overexposure can increase the risk of surface wear, especially on reused or older inserts.

Choosing the Right Cleaning Solution: Chemistry Matters

Ultrasonic cleaning isn’t just about sound waves—it’s a chemical process too. The detergent or solution in the bath needs to match the material and its contaminants. For ceramic inserts, that means avoiding highly alkaline or acidic cleaners that might etch surface coatings or interact with chemical residues.

Instead, opt for a neutral-pH or mildly alkaline solution designed for delicate metals or ceramic composites. If you’re removing built-up machining oils or carbon residues, look for surfactant-enhanced formulations that offer emulsification without aggressive reactivity.

For high-precision applications, it’s wise to finish the process with a rinse in deionized or distilled water to prevent mineral deposits from forming on the ceramic surface. Drying should be done in a clean, lint-free environment—preferably using compressed air or a temperature-controlled oven at low heat (below 70°C) to avoid thermal shock.

Cleaning fluid

Routine Maintenance: Keeping Your Inserts and Your Cleaner in Top Shape

Cleaning ceramic inserts isn’t just about the inserts themselves—it’s about keeping your ultrasonic system operating at peak efficiency too. Residues from coolant oils, broken particles, and even detergent buildup can impair cavitation performance and reduce cleaning quality over time.

Make it a habit to drain and rinse the tank after cleaning heavily soiled loads. If using the cleaner daily, perform a deep clean once a week using a descaling agent compatible with stainless steel tanks. This helps prevent mineral buildup and extends transducer life.

Also, inspect the insert baskets regularly. Wire mesh baskets can wear over time and develop sharp edges that scratch ceramic surfaces during vibration. Use non-abrasive holders or rubber-coated trays if available, especially when cleaning newer or coated inserts.

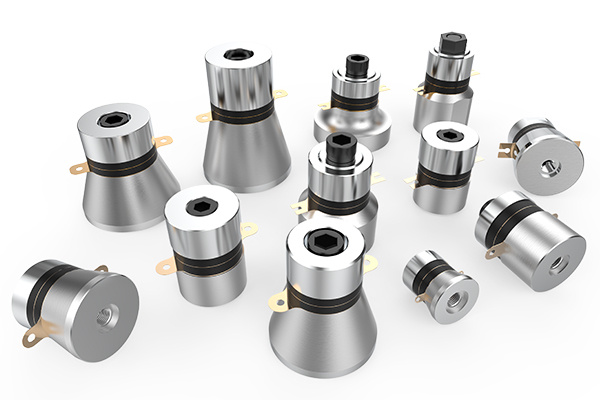

Transducers

When to Rely on Professional-Grade Equipment

There’s a point where lab improvisation and entry-level machines just won’t cut it—especially in facilities that depend on exact tool performance and consistent output. That’s where professional-grade ultrasonic cleaners come in.

Industrial models designed by manufacturers like Granboultrasonic offer features specifically valuable for ceramic insert cleaning: dual-frequency modes, programmable timers, auto-drain functions, and precision heating control. These machines also ensure even distribution of cavitation energy, which helps prevent “hot spots” that can damage parts.

In precision machining or aerospace applications, using certified systems not only improves cleaning results but aligns with quality management systems like ISO or AS9100 compliance. In these environments, a well-maintained insert isn’t just clean—it’s traceable and performance-verified.

Granboultrasonic cleaners

Granbo Ultrasonic

Granbo Ultrasonic