Choosing the Right Ultrasonic Cleaner Solution for Carburetors

Browse Volume:4 Classify:Support

Carburetors are mechanical marvels that rely on tight tolerances and clean internal pathways to perform correctly. Over time, they accumulate varnish from evaporated fuel, carbon buildup, and oil residue that can choke performance. For mechanics, DIY engine rebuilders, and small-engine enthusiasts, ultrasonic cleaning has become a powerful ally in restoring carburetors to like-new condition.

But while the cleaning machine does the heavy lifting, the cleaning solution plays an equally critical role. Choosing the right solution for your ultrasonic cleaner is the difference between a quick rinse and a deep, functional clean.

1 to 3.2L Machine Clean Carburetor And Hardware

Why Ultrasonic Cleaning Is Ideal for Carburetors

Unlike brake cleaner or wire brushes, ultrasonic cleaners reach deep into complex passages. Carburetors contain a maze of small orifices, jets, needle valves, and fuel channels that are difficult to access manually. Spray cleaners may blast surface grime, but they often leave behind hardened fuel residue or microscopic clogs that disrupt performance.

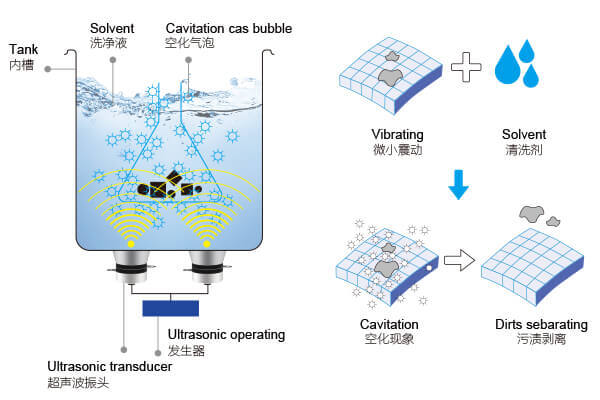

Ultrasonic cleaning works by filling the tank with a cleaning solution and using sound waves to generate cavitation, which consists of millions of microscopic bubbles that implode on the surface of submerged items. These bubbles dislodge particles even in blind holes or narrow bends that no brush could ever reach.

The Principle Behind Ultrasonic Cleaning

This is why ultrasonic technology is trusted in industries ranging from medical device sterilization to aerospace parts maintenance. For carburetors, it means faster, deeper cleaning with less disassembly.

How Ultrasonic Cleaning Works for Engine Parts

The power of ultrasonic cleaning lies in cavitation. When high-frequency sound waves pass through a liquid, they cause rapid compression and expansion cycles. These cycles generate vapor bubbles that collapse violently, creating a scrubbing action that is strong on grime but gentle on metal. Industrial ultrasonic cleaners typically operate in the 20 to 40 kHz range for maximum cleaning power, while household models usually use frequencies between 40 and 80 kHz to balance effectiveness with material safety.

Carburetors respond well to frequencies around 28 to 40 kHz because this range produces larger bubbles that deliver a stronger mechanical impact. For extremely delicate components, higher frequencies around 68 to 80 kHz may be used, but they are less common for engine parts.

However, cavitation alone is not enough. The cleaning solution enhances the mechanical action by softening and emulsifying oils, lifting oxidation, and preventing re-deposition of loosened debris.

What to Consider When Choosing a Cleaning Solution

The ideal ultrasonic solution for carburetors must strike a balance between aggressive degreasing and material safety. Carburetors are often made from aluminum, brass, and zinc alloys, all of which can corrode if exposed to the wrong chemistry.

Here are key factors to keep in mind:

- Non-corrosive formulation: The solution should be safe for aluminum and brass, avoiding acids or harsh alkaline agents.

- Strong degreasing power: Fuel residue, oil, and carbon need to be softened and removed.

- pH-balanced: Mildly alkaline cleaners are often preferred, offering cleaning strength without damaging soft metals.

- Low-foaming: Excessive foaming interferes with cavitation and can damage sensitive ultrasonic components.

- Compatibility with your tank heater: Some solutions perform better at 50 to 65°C, where oils and gums dissolve more efficiently.

Cleaning fluid

Recommended Types of Cleaning Solutions for Carburetors

Water-Based Alkaline Solutions

These are commonly used for ultrasonic cleaning in automotive shops. They work by emulsifying grease and breaking down organic residues. Mild alkaline solutions are safe for aluminum when diluted correctly.

Surfactant-Based Degreasers

These solutions contain wetting agents that lower surface tension, allowing the liquid to flow more easily into tight spaces. They excel at removing light oil, soot, and grime from throttle bodies and jets.

Rust and Oxide Removers

Some carburetors, especially those from older motorcycles or small engines, may have light surface rust or oxidation. There are ultrasonic-compatible solutions with chelating agents that dissolve rust without damaging the metal underneath. These are typically acidic but are formulated to be safe at proper dilution.

Popular Ultrasonic Cleaning Solutions for Carburetors

With so many cleaning formulas on the market, it can be hard to know where to start. Some are made specifically for ultrasonic use, while others are adapted from general-purpose degreasers. Choosing the right one depends on what kind of contamination you’re dealing with and the type of carburetor you’re restoring.

Commercially Available Formulas

Several brands have established reputations among mechanics and restoration professionals. These include:

1. Simple Green Pro HD

Unlike the original Simple Green, which is not recommended for aluminum, the Pro HD version is non-corrosive and safe for use on soft metals. It’s concentrated, so a 1:10 to 1:20 dilution works well in ultrasonic applications.

2. SharperTek Ultrasonic Carburetor Cleaner

Specifically formulated for auto parts, this solution targets carbon buildup and varnish. It’s designed for use at elevated temperatures, around 50 to 60°C, and pairs well with larger ultrasonic tanks in professional garages.

3. Alconox Liquinox

While more often used in laboratory settings, Liquinox is effective at breaking down grease and oil from metal surfaces. It’s low-foaming, biodegradable, and free of phosphates, making it an eco-conscious choice for light cleaning jobs.

4. Zep Industrial Purple Degreaser

This cleaner is strong and economical, often used in large shops. However, it must be diluted properly and not left in contact with aluminum parts for long, as its high alkalinity can etch surfaces.

Homemade Cleaning Solutions

Some experienced users opt for DIY mixtures. These often use dish soap, vinegar, or even Pine-Sol diluted in water. While budget-friendly, these homebrew options carry more risk. For example, vinegar is acidic and can corrode aluminum if not carefully controlled. Dish soaps may foam excessively, disrupting cavitation.

Homemade mixtures should always be used with caution and are best for low-value parts or basic maintenance, not full restorations.

What Professionals Recommend

Mechanics and engine restorers usually prefer commercial solutions that are explicitly labeled for ultrasonic use. These products are tested for compatibility with soft metals, and they offer predictable results. Some professionals also add rust inhibitors or neutralizing agents during the rinse cycle to prevent flash rusting after cleaning.

Important tip: Always read the label and safety data sheet before using a new cleaning agent. Some solutions may look safe but contain additives that are not ultrasonic compatible.

How to Mix and Use the Cleaning Solution Safely

Even the best cleaning solution will not perform well if mixed or used improperly. Here’s how to maximize cleaning power without damaging your carburetor or ultrasonic machine:

- Dilution ratios: Follow the manufacturer’s instructions. Most concentrates require a dilution between 1:10 and 1:20 with water. Too strong, and you risk etching; too weak, and cleaning becomes ineffective.

- Water temperature: Set the tank to around 50 to 60°C. Warm water speeds up emulsification and softens hardened residues.

- Cycle time: Most carburetors clean well in 10 to 20 minutes. Extremely dirty units may need a second run.

- Rinse thoroughly: After cleaning, rinse all parts with clean water to remove any remaining chemicals. A second rinse in distilled water can prevent mineral spotting.

- Dry completely: Use compressed air or a heat gun (on a cool setting) to blow out water from small holes and crevices.

Never leave metal parts soaking in solution longer than necessary, as even mild cleaners can affect plating or anodizing with prolonged exposure.

Avoiding Mistakes When Cleaning Carburetors Ultrasonically

Ultrasonic cleaning is effective, but it is not foolproof. Missteps can lead to damage or ineffective results.

Do Not Use Flammable Solvents

Solvents like gasoline, acetone, or carb cleaner should never be used inside an ultrasonic cleaner. They are highly flammable and can produce hazardous vapors, even if the tank is not heated.

Watch Out for Sensitive Components

Do not place rubber seals, gaskets, or plastic diaphragms in the ultrasonic cleaner unless you’re certain they can handle it. Many of these materials degrade in high-frequency environments or hot cleaning solutions.

Clean the Tank Regularly

Dirty solution not only loses effectiveness but can also cause contamination or staining on parts. Change the solution after every few uses, or more often if the parts are heavily soiled.

Environmental and Safety Considerations

Using ultrasonic cleaners and chemical solutions responsibly is just as important as cleaning effectiveness. Many commercial products are biodegradable or designed to meet local waste disposal standards, but that does not mean they can go down the drain unchecked.

Disposing of Used Solutions

Spent ultrasonic solutions often contain fuel residues, oils, and metallic particles. These contaminants require proper handling. Most localities offer hazardous waste disposal programs that accept small quantities from home users or larger volumes from professional garages.

Do not dispose of used carburetor cleaning solutions in sinks, storm drains, or gardens. Always follow disposal instructions provided on the product label or Material Safety Data Sheet (MSDS).

Handling Concentrated Cleaners

When mixing or handling concentrated solutions:

- Wear gloves and eye protection

- Work in well-ventilated areas

- Avoid mixing cleaners unless the manufacturer approves it

For added safety, keep cleaning agents out of reach of children and store them in clearly labeled containers away from heat sources.

Eco-Friendly Choices

Some brands now offer non-toxic and biodegradable ultrasonic solutions specifically designed for automotive parts. These options are safer for home use and reduce environmental impact without sacrificing cleaning performance.

Granbo Ultrasonic

Granbo Ultrasonic