The Rise of Ultrasonic Cleaners: Revolutionizing Industries with Precision and Efficiency

Browse Volume:236 Classify:Support

Ultrasonic cleaning technology has become a game-changer across a variety of industries. Whether you’re dealing with delicate machinery, medical instruments, jewelry, or automotive parts, the power of ultrasonic waves to clean and restore surfaces is unmatched. The process involves the use of high-frequency sound waves to create microscopic bubbles in a liquid that gently and effectively remove contaminants from surfaces. This technology, which was once considered niche, has gained widespread acceptance due to its effectiveness, precision, and versatility.

1. Understanding the Science Behind Ultrasonic Cleaning

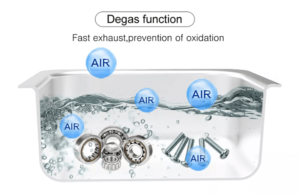

At the heart of ultrasonic cleaning is the principle of cavitation. Cavitation occurs when ultrasonic waves create microscopic bubbles in a liquid medium. These bubbles rapidly expand and implode, producing localized high-pressure waves that break apart dirt, grease, and other contaminants on surfaces. The cleaning process is gentle yet highly effective, making it suitable for delicate components that cannot withstand harsher cleaning methods.

The process typically begins by placing the items to be cleaned into a specialized tank filled with a cleaning solution, usually water mixed with a small amount of detergent. When the ultrasonic waves are applied, the cavitation bubbles gently scrub away contaminants from even the smallest crevices. This makes ultrasonic cleaning ideal for cleaning items with intricate designs, such as jewelry, watch parts, or medical devices.

2. Applications Across Industries

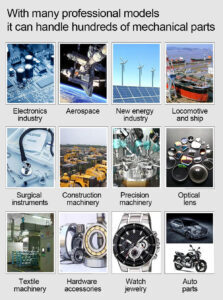

Ultrasonic cleaners have found applications in a wide range of industries, from healthcare and manufacturing to automotive and electronics. Their versatility makes them an essential tool in various settings.

Medical Industry

In the medical field, ultrasonic cleaning plays a critical role in sterilizing surgical instruments, dental tools, and other medical equipment. Precision cleaning is vital to ensure that these tools are free from harmful bacteria, viruses, and residue, which could lead to infections. Ultrasonic cleaners effectively remove blood, tissue, and other biological materials from instruments, which are often difficult to clean with traditional methods.

Automotive and Aerospace

In the automotive and aerospace industries, ultrasonic cleaning is used for cleaning engine parts, fuel injectors, and other precision components. These industries require high levels of cleanliness to ensure that parts operate efficiently and safely. Ultrasonic cleaning removes contaminants that could affect the performance of mechanical parts, making it a preferred method for maintaining the integrity of engines and other critical components.

Electronics Manufacturing

The electronics industry benefits from ultrasonic cleaning in the production and maintenance of circuit boards, semiconductors, and other delicate electronic components. The process is ideal for cleaning components without causing damage, as the ultrasonic waves can reach even the most hard-to-reach areas, removing dust, flux residues, and other contaminants that can affect performance.

3. Key Advantages of Ultrasonic Cleaning

The widespread adoption of ultrasonic cleaning is due to its many advantages over traditional cleaning methods.

Precision and Effectiveness

One of the primary benefits of ultrasonic cleaning is its ability to clean even the smallest crevices and complex surfaces. Traditional cleaning methods, such as scrubbing or using harsh chemicals, may not be effective in reaching these areas. Ultrasonic cleaning, on the other hand, can thoroughly clean intricate parts, ensuring that no contaminants are left behind.

Gentle on Delicate Materials

Unlike abrasive cleaning methods that can scratch or damage surfaces, ultrasonic cleaning is gentle. This makes it ideal for delicate materials, such as glass, gold, and other sensitive substances. In industries like jewelry manufacturing and healthcare, where equipment and materials are often delicate, ultrasonic cleaning helps preserve the integrity of the items being cleaned.

Environmentally Friendly

Ultrasonic cleaning is a more environmentally friendly option compared to traditional cleaning methods that rely on harsh chemicals. The process often uses water-based cleaning solutions, reducing the need for toxic chemicals that can be harmful to both the environment and human health. Furthermore, the ultrasonic cleaning process reduces water and energy consumption, making it a more sustainable option.

Cost Efficiency

Though the initial investment in ultrasonic cleaning equipment can be high, the long-term benefits far outweigh the costs. Ultrasonic cleaners are efficient and can clean multiple items simultaneously, reducing labor costs. Additionally, they reduce the need for expensive cleaning chemicals and offer faster cleaning cycles, increasing overall productivity.

4. The Future of Ultrasonic Cleaning: Innovations and Trends

The ultrasonic cleaning market continues to evolve, with manufacturers developing new and more efficient systems that offer even greater precision and effectiveness. Some of the emerging trends and innovations include:

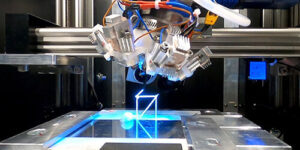

Automation and Smart Technology

As industries become increasingly automated, ultrasonic cleaning systems are being integrated with smart technology. Automated ultrasonic cleaners can adjust settings based on the type of material being cleaned, the level of contamination, and other factors. This adaptability ensures that the cleaning process is optimized for each situation, improving both efficiency and quality.

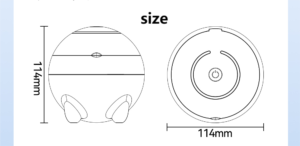

Miniaturization

As ultrasonic cleaning technology improves, systems are becoming smaller and more compact. This miniaturization makes ultrasonic cleaners more accessible to smaller businesses and individual users. For example, small ultrasonic cleaners are now available for cleaning jewelry, watches, and other personal items, making this technology available to a wider audience.

Advanced Cleaning Solutions

Manufacturers are also developing specialized cleaning solutions to enhance the performance of ultrasonic cleaning systems. These advanced solutions are formulated to work in conjunction with ultrasonic waves, providing enhanced cleaning power and making the process more efficient. They are also designed to be gentle on materials, ensuring that delicate surfaces are not damaged during cleaning.

5. Challenges and Considerations in Ultrasonic Cleaning

While ultrasonic cleaning offers numerous benefits, there are some challenges and considerations that must be taken into account when using this technology.

Material Compatibility

Not all materials are suitable for ultrasonic cleaning. For example, soft or fragile materials may not be able to withstand the high-frequency sound waves and could become damaged. It’s essential to assess the compatibility of materials before subjecting them to ultrasonic cleaning.

Cost of Equipment

The initial cost of ultrasonic cleaning equipment can be high, especially for larger or more advanced systems. However, the investment is often justified by the long-term savings in labor, cleaning chemicals, and the improved efficiency of the cleaning process.

Maintenance and Operation

Ultrasonic cleaning systems require regular maintenance to ensure they continue to operate effectively. This includes cleaning the ultrasonic transducers, replacing worn-out components, and monitoring the performance of the cleaning solution. Proper training for operators is also essential to ensure that the equipment is used correctly and efficiently.

Environmental Factors

While ultrasonic cleaning is generally considered environmentally friendly, the impact of the cleaning solution and the disposal of waste must be considered. Some cleaning solutions may contain harmful chemicals that need to be disposed of properly. It’s essential to ensure that waste disposal practices are in compliance with local regulations.

The Growing Role of Ultrasonic Cleaning in Modern Industries

As industries continue to demand more efficient, precise, and environmentally friendly cleaning solutions, ultrasonic cleaners are poised to play an increasingly significant role. From healthcare to automotive, and even the consumer market, ultrasonic cleaning technology has already revolutionized numerous fields. As new innovations continue to emerge, the potential applications for ultrasonic cleaning are expanding, offering even greater efficiency and effectiveness across diverse industries.

The rise of ultrasonic cleaners represents a shift towards smarter, more sustainable, and highly efficient cleaning practices. Whether it’s in precision manufacturing, delicate medical procedures, or jewelry restoration, ultrasonic cleaning is proving to be an indispensable tool in modern industries. Its ability to clean complex parts quickly and effectively while being gentle on sensitive materials makes it a preferred choice for businesses seeking to enhance their cleaning processes. The future of ultrasonic cleaning looks bright, with continued advancements set to further shape industries worldwide.

References:

- Attar, M., & Khodaparast, A. (2022). Ultrasonic Cleaning Technology and Applications in the Medical Field. Journal of Industrial Ultrasonics, 34(2), 98-105.

- Smith, R., & Johnson, T. (2023). Advancements in Ultrasonic Cleaning for Automotive Applications. International Journal of Precision Engineering, 45(4), 212-225.

- Lee, H. & Wong, A. (2021). Environmental Impact of Ultrasonic Cleaning Solutions. Environmental Science and Technology, 29(3), 133-140.

Granbo Ultrasonic

Granbo Ultrasonic