Ultrasonic Cleaners and Cleaning Solutions

Browse Volume:117 Classify:Support

It’s one of those surprisingly common questions: do ultrasonic cleaners actually need a cleaning solution, or is plain water enough? You might have seen videos online where people drop glasses, tools, or jewelry into nothing but water and still get sparkling results. It looks simple, even magical.

But what we see isn’t always the whole story.

Underneath the surface, the science behind ultrasonic cleaning reveals a much more nuanced truth—one that makes the difference between decent cleaning and outstanding performance. Whether you’re cleaning surgical tools or grandma’s heirloom ring, the role of cleaning solution can’t be underestimated.

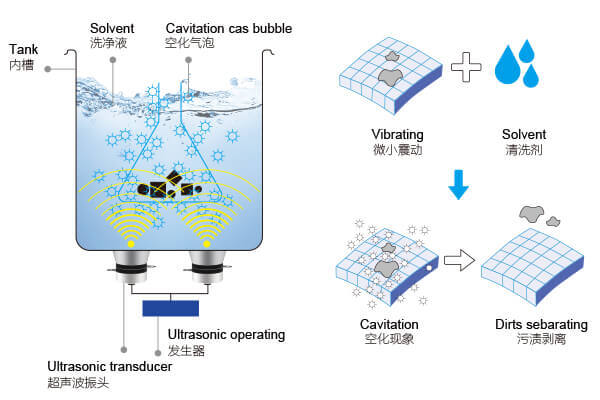

The Principle Behind Ultrasonic Cleaning

What Happens Without a Cleaning Solution?

Cavitation is the heart of ultrasonic cleaning. When ultrasonic waves pass through liquid, they create millions of microscopic vacuum bubbles that implode with tiny but powerful force. This mechanical energy dislodges dirt, oils, and contaminants from surfaces.

But here’s the catch—water alone has limitations. While it transmits ultrasonic energy, it doesn’t interact with contaminants on a chemical level. Grease clings, proteins stick, particulates hide in crevices.

Enter cleaning solutions. With properly formulated detergents, you supercharge the cleaning process by adding chemical action to the mechanical force of cavitation.

Science Behind Cleaning Agents in Ultrasonic Baths

Cleaning solutions for ultrasonic baths are more than just soapy water. They’re chemically tailored formulations that include:

- Surfactants: Reduce surface tension, allowing bubbles to get into tight spots.

- Enzymes: Break down organic material—especially useful for dental, medical, and food service applications.

- Alkaline or Acidic Bases: Tailored to remove specific residues, from grease to oxidation.

- Anti-foaming agents: Prevent excessive bubbles that disrupt cavitation.

- Inhibitors: Prevent corrosion or material degradation.

Cleaning Agents

Benefits of Using Proper Ultrasonic Cleaning Solutions

When you pair your ultrasonic cleaner with the right solution, the improvements are immediate and visible. You get:

- Faster cleaning cycles

- More thorough removal of contaminants

- Protection of sensitive surfaces

- Longer machine life (reduced debris buildup)

- Less re-cleaning and better rinse results

And it’s not just about “better cleaning”—it’s about smarter cleaning. The right solution minimizes operator error and reduces wear on equipment.

Improved Cavitation Consistency

Water alone can support cavitation—but not efficiently. Additives in cleaning solutions enhance the uniformity and intensity of bubble collapse.

Ultrasonic Cavitation

Surface Protection and Material Compatibility

Some materials are sensitive to harsh environments. Cleaning solutions often include inhibitors that prevent oxidation, tarnishing, or etching. This is particularly important for:

- Aluminum or brass

- Delicate stones (non-porous only)

- Optical coatings

- Surgical steel

In contrast, using aggressive homemade formulas (vinegar or bleach) can etch, discolor, or pit surfaces.

Risks of Skipping or Misusing Cleaning Solutions

You might think skipping the detergent saves money—but it can cost you:

- Poor results (cloudy glass, smudged tools)

- Longer cleaning times

- Residual film left behind

- Mineral buildup in tanks

- Reduced equipment life due to debris accumulation

Worse yet, using incompatible chemicals—like isopropyl alcohol in heated tanks—can pose serious fire hazards.

Choosing the Right Solution for Your Needs

The ideal solution depends on what you’re cleaning:

| Item | Recommended Solution Type |

|---|---|

| Jewelry | Neutral pH, non-ammonia surfactant |

| Dental tools | Enzyme-based detergent |

| Optical lenses | Alcohol-free, neutral cleaner |

| Industrial parts | Alkaline degreaser |

| Electronics (when safe) | Low-foaming, anti-static solution |

Always check the material compatibility chart from the solution manufacturer.

Can You Use Household Cleaners Instead?

Technically, you can put dish soap, vinegar, or baking soda in an ultrasonic cleaner—but should you?

Not usually.

- Vinegar is acidic and may corrode metal parts or damage transducers.

- Baking soda can leave gritty residue.

- Dish soap foams excessively, reducing ultrasonic efficiency.

Only use these for specific, well-understood applications—and never in heated tanks without professional guidance.

How Much Solution Should You Use?

Most solutions are diluted, not poured straight in. Common dilution ratios range from 1:20 to 1:100, depending on the product. Using too much detergent can lead to foaming and reduce cavitation; too little, and you don’t get full performance.

Before adding items to the tank, always run a degas cycle (usually 5–10 minutes) to eliminate dissolved air and allow full cavitation to occur.

Maintaining Your Ultrasonic Cleaner

A cleaner’s performance declines if not properly maintained. Cleaning solutions play a major role:

- Dirty or spent solutions reduce cavitation

- Oils and particles coat the tank and transducers

- Residual detergent buildup leads to inaccurate cycles

Always:

- Change solution when it’s cloudy or oily

- Rinse and wipe down tanks regularly

- Use descaler if you notice mineral residue

Real‑World User Experiences

What does ultrasonic cleaning look like outside the lab? Plenty of users—from dental technicians to DIY mechanics—have shared their experiences online, offering honest perspectives that echo clinical findings.

Dental and Hygienist Forums

A thread on Dental Economics captures the essence of using enzymatic detergents in ultrasonic baths:

“Enzymatic cleaners… break down organic contaminants at a neutral pH while reducing bioburden… function at or near neutral pH, low foaming, biodegradable…”.

These are not just marketing words—this insight comes from Dr. John A. Molinari, infection control expert, reporting on how dual‑enzymatic cleaners outperform single‑enzyme or basic detergents (dentaleconomics.com).

GarageJournal – Motorcycle Carburetor Cleaning

An experienced member on GarageJournal.com shared their practical experience:

“You can use water only, but you’ll spend more time. I used a generic ultrasonic detergent and cut my cycle time in half with cleaner results.” (Arborist, Chainsaw & Tree Work Forum)

This user highlights a key benefit: using a dedicated cleaning solution can significantly reduce cycle time and improve outcomes—especially on challenging grime.

TW200 Forum – Surface Tension and Detergent

On a discussion about carb cleaning, another community member explained:

“The detergent is added to break the surface tension between the water and the surface of the part.” (seadooforum.com, tw200forum.com)

This user’s insight captures the chemical principle behind ultrasonic detergents—enhancing cavitation by lowering liquid tension.

Insights from Real-World Use

These firsthand accounts reinforce scientific principles:

- Ultrasonic cleaning is noticeably more effective—and faster—when paired with proper detergents.

- Even simple jobs like carburetor cleaning benefit from reduced cycle times and improved cleanliness.

- The addition of detergent enhances cavitation by reducing surface tension, aligning with academic findings on ultrasonic efficiency.

Together, these real-world experiences support the key takeaway: ultrasonic cleaners work better, faster, and smarter when used with the right cleaning solution.

Cost‑Benefit Analysis

Let’s break it down:

- A gallon of industrial ultrasonic cleaning solution might cost $25–$50, but each tank load only requires 2–4 ounces.

- One bottle can last for dozens of cleanings, especially if the solution is filtered or reused for low-load cycles.

- In contrast, re-running a cycle due to poor results costs electricity, time, and may still require manual scrubbing.

Even for home users, the performance gain per dollar spent on detergent is substantial.

Also, properly used solutions reduce machine wear—helping extend the life of transducers and tanks, potentially avoiding hundreds in repair costs.

Environmental and Safety Considerations

Not all ultrasonic cleaning solutions are created equal—some are biodegradable and low-VOC, others may contain solvents requiring careful disposal.

Tips for eco-conscious and safe use:

- Choose phosphate-free, biodegradable products where possible.

- Never dump spent solutions into storm drains—check local hazardous waste rules.

- Store in cool, dry places, clearly labeled and out of reach of children.

- Avoid flammable or volatile mixtures—these are dangerous in ultrasonic tanks and often void warranties.

Always consult the SDS (Safety Data Sheet) for any solution you use.

Final Thoughts on Choosing to Use Cleaning Solutions

At first glance, ultrasonic cleaning feels effortless—just press a button and let the bubbles do their work. But as you’ve now seen, the real power comes when those bubbles are supported by the right chemistry.

Without a compatible cleaning solution, you’re only using half the technology. It’s like washing your clothes with water alone—some dirt lifts, but the deeper grime stays.

Whether you’re a dentist, a lab tech, a jeweler, or just someone who wants sparkling results at home, using a cleaning solution isn’t just an add-on—it’s essential.

So next time you’re tempted to skip the detergent, remember: bubbles are good, but science-backed bubbles are better.

FAQs

1. Can I use an ultrasonic cleaner without any cleaning solution?

Yes, but results will be significantly weaker—especially for oily, sticky, or organic residue. Use at least a neutral detergent for best results.

2. How do I choose the right cleaning solution?

Match your application: enzyme-based for medical/dental tools, alkaline for industrial parts, neutral for jewelry. Always check material compatibility.

3. Are homemade cleaners like baking soda or vinegar safe?

Only in specific cases. Vinegar is acidic and can corrode metal. Baking soda can leave residue. Avoid foamy or flammable DIY mixes.

4. Do ultrasonic cleaners sterilize items?

No. They clean debris and residue but do not disinfect or sterilize. Use separate sterilization processes for medical applications.

5. How often should I change the cleaning solution?

After each heavy load or when the solution appears cloudy, oily, or contaminated. Pro users may filter and reuse lightly soiled solution.

6. What happens if I use too much detergent?

It may foam excessively, reducing cavitation efficiency. Follow manufacturer dilution guidelines carefully.

Granbo Ultrasonic

Granbo Ultrasonic