How to make industrial ultrasonic cleaners have better cleaning effect?

Browse Volume:1282 Classify:Support

Over time, the cleaning effect of the previously purchased industrial ultrasonic cleaner was as though it had not been well enough to meet its own psychological requirements, but it had not reached the necessity of replacing the equipment. So how should we be able to effectively enhance the cleaning effectiveness of industrial ultrasonic cleaners in this situation?

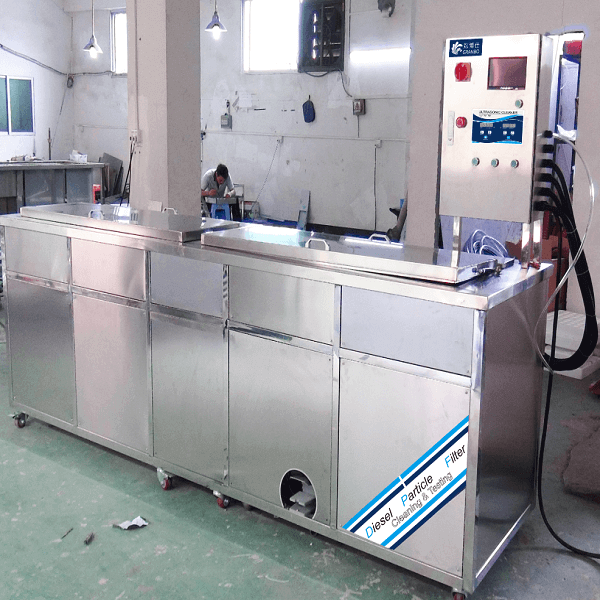

Ultrasonic cleaner factory

1、 Maintenance is important for the industrial sonic cleaner

(1). Regular maintenance and maintenance of technical requirements are simple and low cost while guaranteeing the normal operation of equipment, reducing the wear of parts, and prolonging the life of equipment so that enterprises can more scientifically and rationally configure limited resources, while at the same time, to “nodding, open-source” purposes.

(2). The shorter the years of device use, the higher the reliability, and the longer the years of use, the lower the reliability. The lower the reliability is that a mechanical device is prone to failure, the more tangible wear and tear of the device, and the greater the cost required to repair it. Modern mechanical equipment is a highly funded equipment, and the cost of equipment investment and use is quite expensive, which urgently demands the economic benefits of equipment management. Therefore, it is imperative to reduce tangible wear and tear of equipment and reduce repair costs and other abnormal expenses during the life cycle of the equipment through routine maintenance and maintenance of the equipment.

Ultrasonic cleaning machine factory

2、 Specifications for industrial ultrasonic cleaning machine operational use

(1). Choice of cleaning agent

Washing agents were chosen correctly based on different cleaning objects. Cleaning agents are generally divided into aqueous (basic) cleaning agents, organic solvent cleaning agents, and chemical reaction cleaning agents. Commonly used are water-based detergents.

While ultrasonic cleaners have many, many more numerous products of malaise on the market, so how to choose a suitable product is critical.

When buying ultrasonic cleaners, it is important to ask clearly the relevant technician, to choose them when confirming that the product is suitable, and to have a reliable after-sales service, which is otherwise easy to ask many questions.

Degreasing powder

Metal-detergent

(2). Choice of cleaning solution temperature

The temperature of cleaning is an important factor affecting the cleaning speed, and appropriate increasing the temperature of the cleaning solution can enhance the cavitation capacity and shorten the cleaning time, but beyond a certain temperature, due to the corresponding increase in the vapor pressure that paradoxically decreases the cavitation effect, it is necessary to maintain a certain temperature range, such as the water solvent cleaning solution is generally around 45 ° C and the trichloroethene cleaning solution is around 75 ° C. The choice of cleaning solution must take into account that the chosen viscosity of the cleaning solution is small and the surface tension is small to favor cavitation of the cleaning solution.

Improved cleaning

3. The ultrasonic intensity (power density) was chosen

I.e., unit area acoustic power. The good or bad performance of ultrasonic cleaning depends on the cavitation effect, while the generation of cavitation is related to ultrasonic intensity. Under usual circumstances, aqueous solutions with unit area acoustic power exceeding 0.3 w / cm2 (output power generally greater than 1 W) are capable of cavitation. Within a certain range, the greater the ultrasonic intensity, the more obvious the cavitation effect, that is to say, the better the cleaning effect. But too high power density can damage the machining by causing surface erosion to the workpiece due to too strong cavitation. In addition, when the power density increases to a certain degree, saturation will occur and the cleaning effect will decrease instead. There is also a relationship between the power density critical point to produce cavitation and frequency, the higher the frequency, the greater the power density to produce cavitation, for example, 16 – – 20 kHz, the power density critical point is about 0.3 – – 0.4 w / cm2; 26 – – 30kHz, the power density was chosen as 0.5 – – 0.8w/cm2; 30 – – 40KHz, the power density should be chosen as 1 – – 1.2w/cm2.

4. The frequency of ultrasonic cleaner was chosen

Ultrasonic vibration frequency has a great effect on the cleaning effect, which is due to the fact that ultrasonic frequency has a great effect on the cavitation effect. It was experimentally demonstrated at equal power that cavitation is easily excitable at low frequencies. That is, the lower the frequency, the better the cavitation effect, but the greater the noise. Conversely, the higher the frequency, the worse the cavitation effect and the less the noise.

Granbosonic is a professional ultrasonic cleaner manufacturer and ultrasonic cleaner supplier, and we look for global ultrasonic cleaner distributors.

Granbo Ultrasonic

Granbo Ultrasonic

Hello!