Study on Ultrasonic Power Frequency of Ultrasonic Generator Circuit PCB Board

Browse Volume:1334 Classify:Support

1、 Overview of ultrasonic power supply

Ultrasonic power supply is usually called ultrasonic generator. Its function is to convert electric energy into high-frequency AC signal matching with ultrasonic transducer. From the perspective of amplification circuit, linear amplification circuit and switching power supply circuit can be adopted. Considering the conversion efficiency, high-power ultrasonic power supply generally adopts the circuit form of switching power supply. Linear power supply also has its unique application range. Its advantage is that it can not strictly require circuit matching, allowing continuous and rapid changes in working frequency. From the current situation of the ultrasonic industry, ultrasonic is mainly divided into self-excited and other excited power supplies.

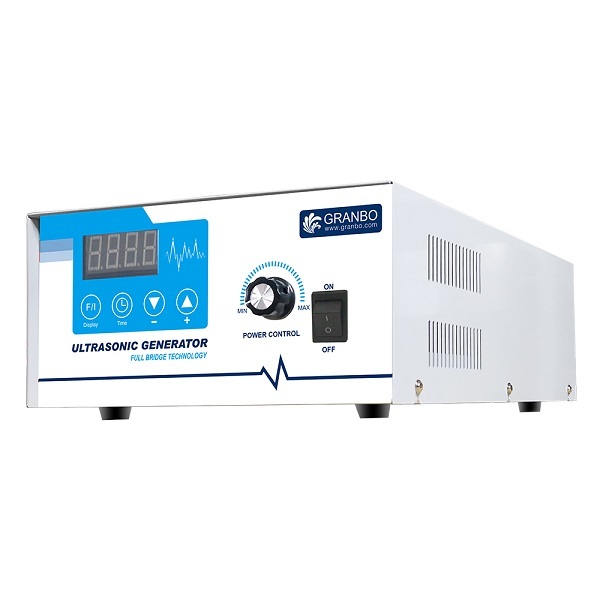

Ultrasonic Generator 01

The principle of ultrasonic power supply is that first, the signal generator generates a signal of a specific frequency, which can be sinusoidal signal or pulse signal. This specific frequency is the frequency of the transducer. Generally, the ultrasonic frequencies used in ultrasonic equipment are 20kHz, 25kHz, 28kHz, 33khz, 40KHz, 50KHz, 55KHz, 60KHZ; 100kHz, 120kHz, 135KHz or above 175kHz have not been widely used yet. However, with the continuous development of precision cleaning in the future. It is believed that the application area will gradually expand.

Ultrasonic power circuit provides frequency tracking signal. When the transducer works at the resonant frequency point, its efficiency is the highest and its work is the most stable, and the resonant frequency point of the transducer will change due to assembly reasons and work aging. Of course, the frequency of this change is only drift, and the change is not great. The frequency tracking signal can control the signal generator, so that the frequency of the signal generator can track the resonant frequency point of the transducer within a certain range. Let the generator work at its best. Of course, with the development of modern electronic ultrasonic technology, especially microprocessor (up) and signal processor (DSP), the function of generator is more and more powerful, but no matter how it changes, its core function should be the content mentioned above, but the ultrasonic technology is different in the implementation of each part.

Ultrasonic Generator 02 Black

2、 Classification of ultrasonic power supply

According to the design, ultrasonic power supply is divided into self-excited power supply and other excited power supply.

There is no signal source in the self-excited circuit, which integrates the oscillation, power amplifier, output transformer and transducer to form a closed loop. The loop meets the amplitude and phase feedback conditions to form a power amplified oscillator. And resonates on the mechanical resonance frequency of the transducer. It is generally used in small equipment with a small number of ultrasonic transducers; However, in the case of a large number of ultrasonic transducers, the resonance effect cannot be achieved through debugging. Therefore, at present, the ultrasonic power supply of industrial ultrasonic cleaning equipment mostly adopts the alternative excitation mode.

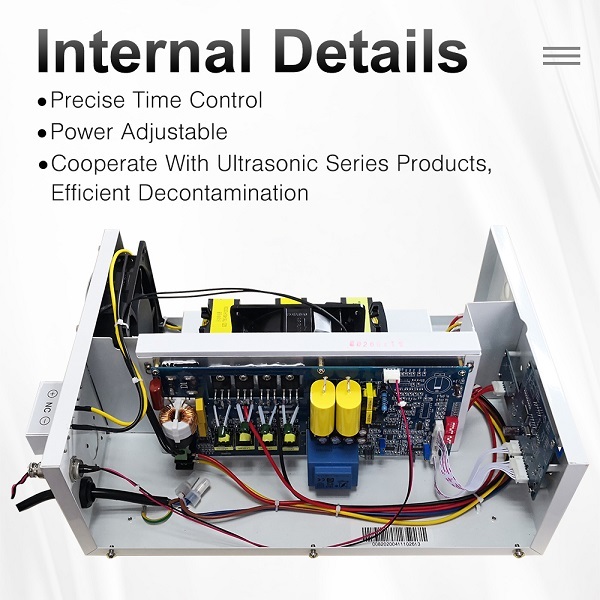

The structure of the shunt power supply mainly includes two parts, the first stage is an oscillator and the second stage is an amplifier. Generally, the ultrasonic energy is added to the transducer through the coupling of the output transformer. The circuit of alternative excitation mode consists of two parts, namely, the signal source part and the signal amplification part.

The signal source part adopts the signal generation and control part with CPU as the core, which is generally driven by 12-15v voltage to generate square wave signals for the signal amplification circuit; The timing control, adjustment and other additional functions of the ultrasonic power supply can be completed by controlling the signal output mode of the signal source. With low-voltage control, the safety and reliability will certainly be high.

The signal amplification part amplifies the signal generated by the signal source and outputs it to the ultrasonic transducer. The difference of output circuit and voltage of ultrasonic power supply with different circuits is an important reason for the high and low propagation efficiency. When the output voltage is low, the generator naturally consumes a large amount of electric energy. At the same time, the vibrator is also easy to heat up and the induced electric field is strong. Properly adjusting the circuit and increasing the voltage output to the ultrasonic transducer may achieve good results.

Ultrasonic Generator 03

In addition, according to the type of devices used in the final power amplifier, there are four kinds: electronic tube ultrasonic power supply; Silicon controlled inverter ultrasonic power supply; Transistor ultrasonic power supply and power module ultrasonic power supply. At present, the electronic tube type and silicon controlled inverter type have been basically eliminated, and the transistor power supply is widely used at present.

Granbo ultrasonic power supply (ultrasonic generator) power division range:

50W-100W、200W-300W、400W-600W; (small power and size can be customized) 600w-900w, 1200w-1500w, 1800w-2100w, 2400w-2700w, 3000W (the high-power external ultrasonic generator is in the form of control box, and the sizes are 350*290*130mm, 370*290*130mm, 390*350*130mm and other specifications)

Frequency range: 20khz-200khz

3、 Mode of ultrasonic generator

a. Single frequency ultrasonic cleaning mode

b. Sweep ultrasonic cleaning mode

c. Dual frequency (multi frequency) ultrasonic cleaning mode

d. Pulse demonstration

Ultrasonic Generator 04

Granbo Ultrasonic

Granbo Ultrasonic

Hello!