Precautions and advantages of power supply for ultrasonic cleaner

Browse Volume:1271 Classify:Support

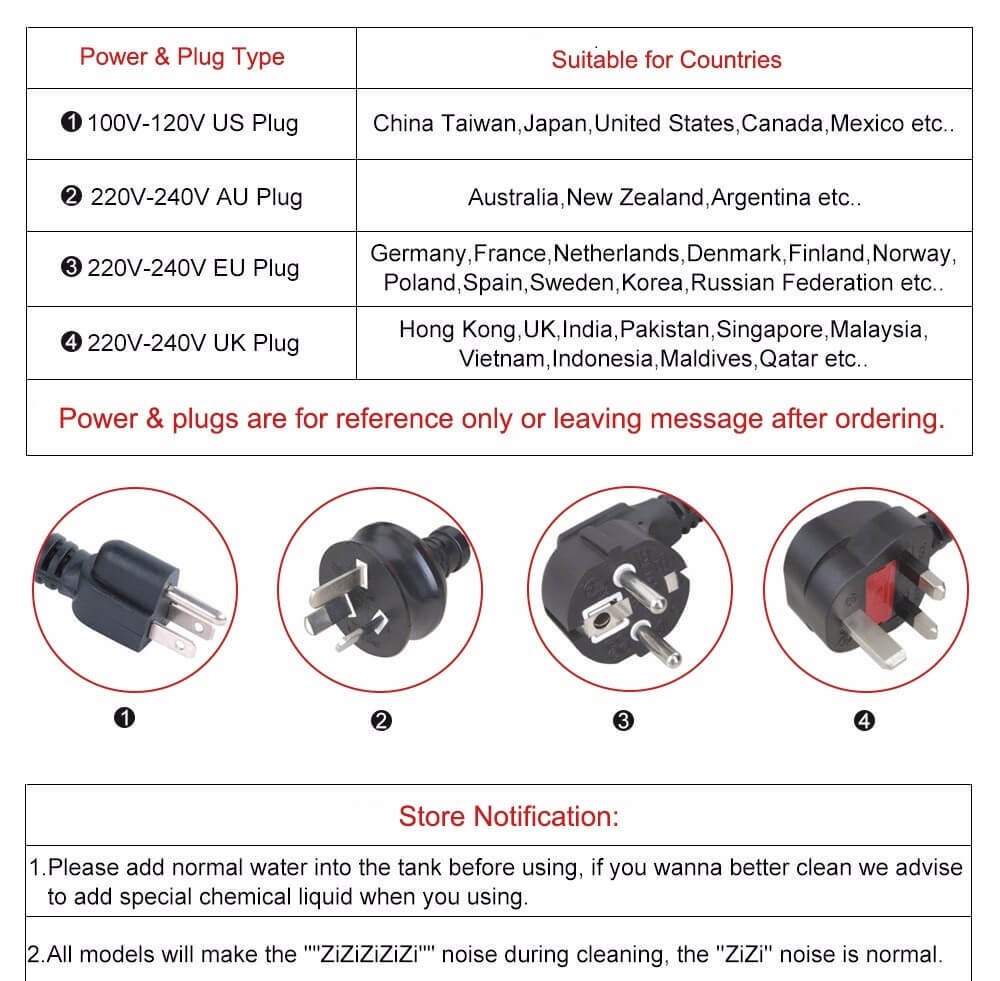

The switching power supply of ultrasonic cleaning machine is also called ultrasonic switching power supply. Its function is to convert people’s voltage (230V or 220V, 60 or 65 Hz) into high-frequency AC signal corresponding to the ultrasonic transducer. 110v – 220v, 220v or 240v AC Voltage, 50khz 60khz Available. EU US AU UK Plug available.

Plug size

From the perspective of amplification circuit mode, linear amplification circuit and switching power supply circuit can be selected. From the perspective of transformation efficiency, power ultrasonic switching power supply usually adopts the power circuit mode of power transformer. Linear regulated power supply is also its unique application category. Its advantage is that it can not strictly manage the matching of power supply circuits, allowing the continuous and rapid change of output power. From the current situation of the ultrasonic industry, the key of ultrasonic is divided into self-excited and other excited switching power supply; The key to the application of ultrasonic switching power supply is to match the output power size, frequency height and capacity of the ultrasonic transducer. The self-excited type can be applied to those with small power, and the non excited type is proposed to be applied to those with large output power.

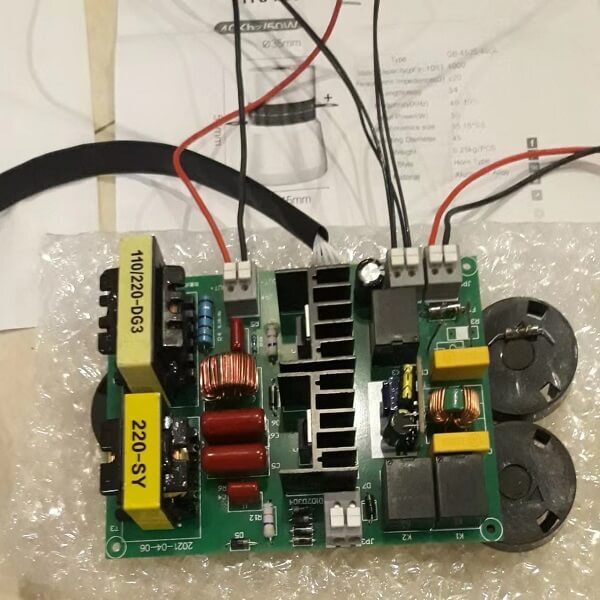

ultrasonic cleaner parts

Operating instructions for ultrasonic cleaner:

1. Three core power sockets (phase wire, ground wire, and grounding wire) for switching power supply (230V) of ultrasonic cleaning machine.

2. Cleaning liquid or water must be added to clean the tank. The liquid level of cleaning liquid or water shall not be less than one-third of the height-width ratio of the cleaning tank (the best part shall be flush with the upper edge of the basket). When cleaning, please add detergent according to different cleaning regulations to improve the cleaning efficiency. All detergents must comply with the regulations that do not erode the inner tank and myocardial cells of the cleaning machine.

3. Put the chemicals to be cleaned into the metal frame, and set the cleaning time according to the scale level of the cleaning substances, usually 3-12 minutes. For the chemicals that are very difficult to clean, the cleaning time can be appropriately increased. (it is forbidden to immediately put the cleaning chemicals at the bottom of the cleaning tank for application).

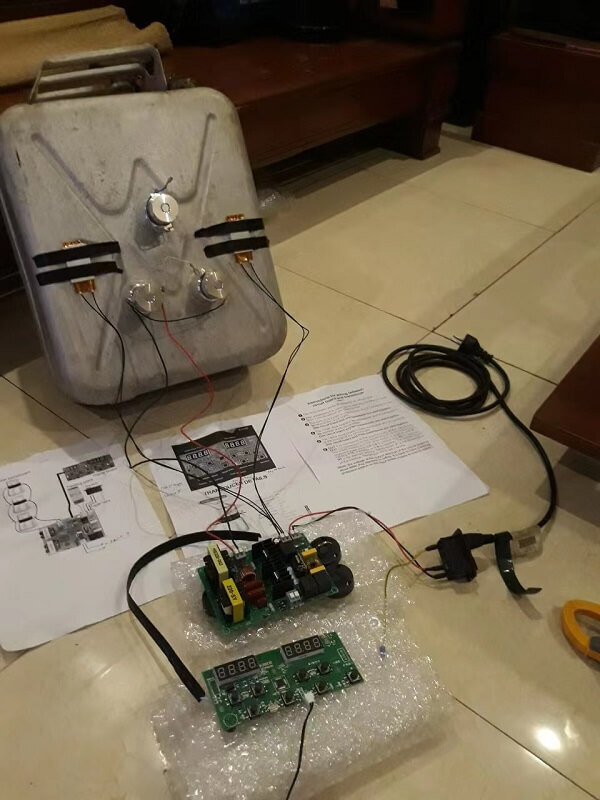

ultrasonic cleaner parts 1

4. Add the 230V three core power plug to the power cord plug of the ultrasonic cleaning machine, turn on the main power switch, set the ultrasonic working time, and press the “start/stop” key to just start working. At this time, the liquid level shows arachnoid fluctuations, accompanied by vibration, indicating that the cleaning machine has entered the working state.

5. Heavy objects should be suspended in the cleaning fluid according to the hanger.

How to judge the common faults of ultrasonic cleaning machine

ultrasonic cleaner parts 2

1. when the power switch of the ultrasonic cleaning machine is turned on, the indicator light is not on.

Reason:

A. The power switch is damaged and there is no power input;

B. Fuse acfu is blown.

2. after the power switch is turned on, the indicator light is on, but there is no ultrasonic output.

Reason:

A. The connecting plug between the transducer and the ultrasonic power board is loose;

B. Fuse dcfu is blown;

C. Ultrasonic power generator failure;

D. Transducer failure.

3. DC fuse dcfu is blown.

Reason:

A. Rectifier bridge stack or power tube is burnt out;

B. Transducer failure.

4. after the power switch is turned on, the machine has ultrasonic output, but the cleaning effect is not as ideal.

Reason:

A. The liquid level of cleaning fluid in the cleaning tank is improper;

B. Ultrasonic frequency coordination is not adjusted properly;

C. The liquid temperature in the cleaning tank is too high;

D. Improper selection of cleaning fluid

Granbo Ultrasonic

Granbo Ultrasonic

Hello!