The Ultimate Guide to Ultrasonic Cleaning

Browse Volume:1258 Classify:Support

The Ultimate Guide to Ultrasonic Cleaning

Ultrasonic cleaners are amazing tools that allow you to perform in-depth cleaning on almost any object. From jewelry to watches, tools, firearm components, fuel injectors, carburetors and coins, it is hard to find a limit to what they can clean. Ultrasonic cleaning is a gentle but invasive cleaning method that, because of modern technology, anyone can do at home.

To get the best results from your ultrasonic cleaner, it is important to know the best way to use it. In this article I will explain how an ultrasonic cleaner works, give tips and techniques and share which cleaning solutions are best to use.

Let’s dive in!

What is ultrasonic cleaning?

Ultrasonic cleaning is a method of cleaning that uses ultrasound and a liquid to clean objects. Because it is thorough but non-abrasive, it is often used to do the final cleaning of fragile components. For the best results a specialized solution is added to the ultrasonic cleaner, but plain water with an added detergent often gives good results as well.

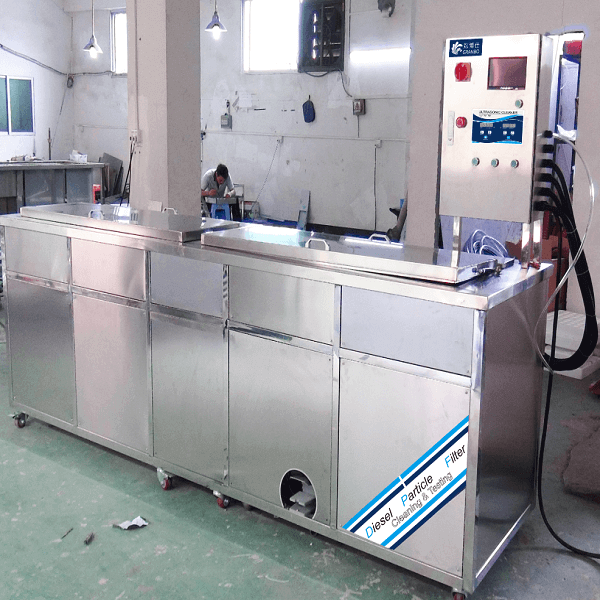

Ultrasonic cleaner factory

How does ultrasonic cleaning work?

As the ultrasound (usually 25-42 kHz) waves pass through the liquid in the ultrasonic cleaner, many microscopic vacuum-filled bubbles rapidly expand and collapse. This is an effect known as acoustic cavitation. The ultrasonic waves cause these miniscule bubbles to collapse, which in turn generates high temperatures (up to 5000 °C) and enormous forces in the liquid.

Because this all happens on a small scale and because the bubbles’ expand and collapse cycle is extremely short, the liquid only becomes mildly warm instead of absurdly hot.

The accumulative effect of the millions of imploding bubbles is what causes the cleaning effect of ultrasonic cleaning. Grease, rust, flux and other contaminants break apart and flow into the liquid. With the right cleaning solution, this is a very effective cleaning method.

real pics show

What are the benefits of ultrasonic cleaning?

You might be wondering why ultrasonic cleaning is one of the best cleaning methods. It has many benefits, especially compared to cleaning by hand. Most notably, ultrasonic cleaning is thorough, fast, efficient and last but not least, anyone can do it. Let’s look at the benefits in more detail.

Ultrasonic-Cleaner-03 (1)

- Clean a wide range of contaminants. There are few limits to the contaminants an ultrasonic cleaner can clean and remove. Some examples of contaminants are grease, oil, dirt, dust, rust, pigment, lime scale, flux, burned on carbon, fingerprint oils and polishing compounds.

- Thorough cleaning. Ultrasonic cleaning removes down to the smallest dirt and particulates. After a full cleaning cycle with the right cleaning liquid, objects can come out looking like new.

- Gentle. While the cleaning is thorough, it is also fairly gentle and is unlikely to cause damage. This makes ultrasonic cleaners great for cleaning jewelry, watch components or other delicate objects.

- Clean hard-to-reach spots. With an ultrasonic cleaner, you are not only able to clean exposed surfaces, but also the more hard-to-reach and even hidden areas. This makes it particularly useful for cleaning things like fuel injectors, carburetors and other complex parts.

- Clean multiple objects at once. Assuming that the cleaner is big enough, you can add additional parts to the tank and clean them without any extra effort.

- Easy to learn. It does not take a lot of time or effort to learn how to use an ultrasonic cleaner. Practically anyone can use one.

- Time-efficient. While an ultrasonic cleaning cycle can take a while depending on the object being cleaned (usually from about 2 up to 20 minutes), you can simply set up the machine and then do something else.

- Low maintenance. Ultrasonic cleaners are relatively simple devices and do not require a lot of maintenance.

- Cost-efficient. Because ultrasonic cleaning is easy to learn, easy to do and does not involve a lot of additional time for maintenance, it is very cost-efficient. Time is money after all.

- Safe. Unlike with manual cleaning, there is no risk of cuts or injuries when cleaning drill bits, scalpels or other sharp instruments when using an ultrasonic cleaner. In addition, there is no need to work with aggressive solvents that are likely hazardous to your health.

Granbo Ultrasonic

Granbo Ultrasonic

Hello!